|

Hydro Steering Bible By Bill "BillaVista" Ansell |

|

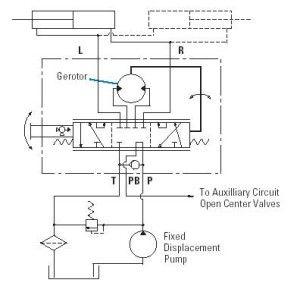

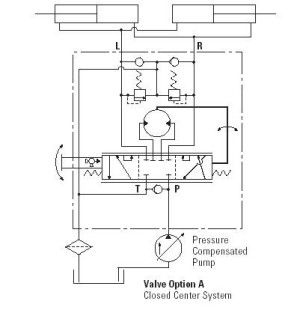

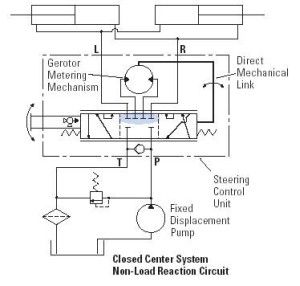

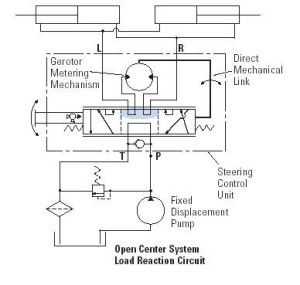

Various hydraulic steering system configurations. | ||||||||||||||||||||||||||||||||||||||||||||||||||

Note that the type of steering of most interest to us as 4 wheelers is "Ackerman" type steering - meaning a steering system whereby the front wheels are steered and travel in different arcs as the vehicle turns. Enterprising 'wheelers initially began by adapting agricultural and industrial hydrostatic steering systems to recreational 4x4s. However, due to the nature of hydrostatic steering, this approach can have wildly varying results, depending on the match between the steering system being cannibalized or emulated, and the desired performance of the 4x4 in question. Most recently, companies such as Performance Off-road Systems have sprung up and begun designing, custom building, and marketing hydrostatic steering systems specifically for the needs of the recreational and competition 4x4 market. Why use hydrostatic steering? Why exactly is hydrostatic steering (hydro steering) so widely used in agriculture and industry, and why has it become so popular for four wheelers? There are a number of distinct advantages: Power - depending on system design parameters (flow, pressure, cylinder size, etc.) hydro steering can develop steering force FAR in excess of any other mechanical, electrical, or hydraulically boosted system. This is a must for massive construction equipment. It is also extremely advantageous to 4x4s with big tires, locker differentials, low tire pressures, the must negotiate and be steered in extremely challenging terrain. For a given amount of steering input effort, no other system can match the power output of a hydro steering system. Flexibility - the very nature of fluid power (hydraulics) allows for great flexibility in system design and mounting. The steering need not be constrained by the requirements for mechanical linkages. Operator comfort - because of the power generated, required operator input levels are very low in hydro steering systems. Control - depending on system design and tuning, precise, custom steering can be arranged, (for example, a system with very few turns of the steering wheel from lock to lock) Weight - the power to weight ratio of hydrostatic systems generally far outstrips traditional hydraulically boosted mechanically actuated steering systems. Smoothness - hydro steering systems are smooth and quiet in operation. Vibration is kept to a minimum. kickback, bump steer, and operator fatigue are all but eliminated. Overload protection - when properly designed, automatic valves can guard the system against a breakdown from overloading. What does Hydrostatic Steering look like? OK, so we know what it is, where it comes from, and why we'd want to use it. Next question is - what does it look like? What are its components? |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

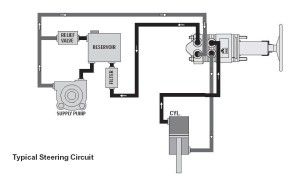

A common, standard, hydrostatic steering system. | ||||||||||||||||||||||||||||||||||||||||||||||||||

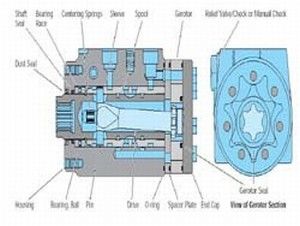

The component in the top right of the picture is the hydraulic steering directional control valve / metering section; and is the heart of the system. Note, many many people erroneously refer to this as an "orbital valve". This is incorrect. The hydraulic industry does not refer to them as "orbital valves". Orbital is a nomenclature (name) reserved for referring to a specific type of hydraulic motor, that has nothing to do with hydro steering. Not one of the the 3 major US manufacturers refers to their steering valves as "orbital valves". However, Eaton/Car-Lynn does market a hydrostatic steering unit that has the trade name Orbitrol™ and this may be where the error originates. From Eaton's website - "ORBITROL™ is a hydrostatic(fully fluid linked)power steering composed of a feedback metering organization with a directional control valve and servo feedback operated with a very small power." There are also valve's in existence that are known in industry/engineering as "orbital valves" but they are not what we are interested in. So, you can really call it whatever you want I suppose, and many many big names in the 4x4 world call it an "orbital valve" but be advised that none of the "big 3" manufacturers do. Parker/Ross calls it a hydrostatic steering unit, as does Sauer-Danfoss, and Eaton/Char-Lynn calls it a "steering control unit (SCU)"; so if you need to discuss them with, say, a hydraulics engineer, it may be advantageous to use the name by which they are properly known. For the remainder of the article I shall refer to it as simply the "steering unit". There is a good reason for all this pedantic semantics - you see, the steering unit is more than just a valve, it is a valve and a metering unit - more on this later. First I will translate the names of the above components into more familiar automotive based names, and then we can trace the circuit to gain a brief preliminary understanding of it's workings. For a detailed look at the basics of hydraulic circuits and components, refer back to Basic Hydraulics of this article series. Reservoir - this is the hydraulic fluid (or power steering fluid) reservoir that stores the fluid necessary for the system. Supply pump - this is the power steering pump, note that in many automotive applications the pump and reservoir are integrated into one unit. Relief valve - this is simply a pressure relief valve, such as you might be familiar with on a shop air compressor. If a malfunction in the system causes the pressure to rise too high, the relief valve opens and the fluid simply passes back to the reservoir. In virtually (absolutely?) all automotive power steering pumps, the relief valve is built into the pump. You are already familiar with it's operation. You will recall from Basic Hydraulics that the pressure the pump produces is directly affected by the resistance to the flow of fluid (for those of you who didn't - think of an engine, the pressure in the combustion chamber builds because of the "resistance' of the cylinder head being in place, remove the "resistance" by removing the head, and no pressure is built up. Lessen the resistance (by making the combustion chamber larger) and you reduce the pressure built up.) In your everyday car's power steering, when you turn the steering to the stops, great resistance (to further steering / continued fluid flow) is caused, resulting in a large increase in pressure, and so the internal relief valve opens and passes the high pressure fluid back to the reservoir (so that component damage is not caused by the high pressure). This causes a great deal of resonance, which is the groan or squeal you here when you turn the steering to the stops and keep trying to turn. Doncha just love understanding how stuff works! Steering unit (top right) - similar in function to the automotive "steering box", it is the part that translates operator input at the steering wheel (shown attached in the pic) to actual movement of the steered wheels. More details on how it works later on. Steering wheel and steering column - self evident, these are the means of operator input. Cyl. - Meaning cylinder, this is the hydraulic actuator (the bit that does the work when supplied with a flow of pressurized fluid); it is roughly analogous to the gearbox and mechanical linkage in a traditional steering setup. It is often erroneously called the "ram" in common usage. This is wrong, because a ram is a particular type of hydraulic cylinder that would be wholly unsuited in a steering system. Technically, the correct term for the types of cylinders used in 4x4 steering systems are non differential cylinders, or double-acting piston-type cylinders (see Part 1 for the basics of cylinders, or further down for more on steering cylinders). "Cylinder" is an appropriate short-from, but "ram" is misleading. Filter - fluid returning from the cylinder / steering unit to the reservoir is first filtered by some sort of filter. This ensures proper condition fluid, the number one factor for satisfactory hydraulic system performance. This is just a very basic circuit, and doesn't show other possible components such as auxiliary fluid coolers, pressure gauges, temperature gauges, and other hydraulic equipment (such as hydro-boost brakes or rear-steer) How it works (tracing the circuit). The reservoir supplies fluid to the pump. The pump pumps the fluid to the steering unit. When the operator turns the steering wheel, connected to the steering unit via the steering shaft, the steering unit directs pressurized fluid to and from the cylinder. In response, the cylinder extends or retracts. The cylinder is connected to the steered wheels, and therefore the wheels steer. Fluid then returns to the reservoir from the steering unit via the filter. Variations on this basic theme are extremely likely, my own system is somewhat different, in that it incorporates an additional circuit for hydro-boost brakes, a second reservoir, an auxiliary cooler, and a combination cooler/filter/reservoir unit. However, it's basic function is exactly as described. Before we cover some more terms and definitions regarding hydro steering and then examine each of these components in greater detail, here are some sneak-peak pics of my own system components from Performance Off-Road Systems. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

Cooler / Filter / Reservoir combination. | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

Modified "P" style saginaw pump. | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

Danfoss steering unit with steering column attached. | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

Steering unit and steering column seperated. | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

Balanced, double-acting, double-ended cylinder. | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

Cylinder installed (test fit). | ||||||||||||||||||||||||||||||||||||||||||||||||||

Component details Pumps: All pumps create flow. They operate on the displacement principle. Fluid is taken in and displaced to another point. Pumps that discharge liquid in a continuous flow are non positive-displacement type. Automotive power steering pumps are non positive-displacement type pumps. With this type of pump, the volume of liquid delivered for each cycle depends on the resistance offered to flow. A pump produces a force on the liquid that is constant for each particular speed of the pump. Resistance in a discharge line produces a force in the opposite direction. When these forces are equal, a liquid is in a state of equilibrium and does not flow. If the outlet of a non positive-displacement pump is completely closed, the discharge pressure will rise to the maximum for a pump operating at a maximum speed. A pump will churn a liquid and produce heat. Non positive-displacement pumps provide a smooth, continuous flow; pressure can reduce a non positive pump’s delivery. High outlet pressure can stop any output; the liquid simply recirculates inside the pump. Non positive-displacement pumps, with the inlets and outlets connected hydraulically, cannot create a vacuum sufficient for self-priming; they must be started with the inlet line full of liquid and free of air. The most common pump used in 4x4 Hydro steering setup is an automotive power steering pump. This makes sense since they are cheap, readily available, easy to mount and run, are designed for the environment, are relatively cheap, and produce reasonable flow while being capable of developing sufficient pressure for our needs. The exact make and type of pump used will likely depend mostly on what fits the engine application easily. The most popular pump is the venerable Saginaw pump, which generally comes in 2 broad styles, the "P" style pump and the "TC" style pump. Regardless of the exact style or part number of automotive power steering pump you use, it will be a fixed displacement type. That means that it always produces flow (as opposed to a variable displacement pump that only produces flow in response to demand) and the GPM output (flow) can be changed only by varying the drive speed of the pump. If the flow is not required (i.e. the hydraulic circuit is in the neutral position - that equates in a hydro steering system, to the steering wheel being centred and there is no steering input from the operator), fluid flow is internally bypassed back to the reservoir. This type of pump (fixed displacement) can be used in an open-center system - the "open-center" means that the control-valve spool (in our case, the steering unit) must be open in the center to allow pump flow to pass through the valve and return to the reservoir. This will become very important later, when it comes time to understand / select the steering unit for the system, as the type of pump and type of steering unit MUST be compatible. (i.e. you cannot use a fixed displacement type pump with a steering unit designed for use with a variable displacement pump). Saginaw "P" style pump The "P" style saginaw pump is like that which is found in a HUGE number of oem cars and trucks. Very often it has an attached, integral fluid reservoir, and is called the "can-o-ham" pump because the teardrop shaped reservoir is reminiscent of the shape of an old-fashioned canned ham. There are also variants that have a more circular or round shaped integral reservoir, along with a secondary remote reservoir - most notably pumps for vehicles such as 1 ton 4x4s and diesel trucks that use hydro-boost brakes. Depending on the exact model of the pump, "P" style saginaw pumps are rated for anything from 2.4 to 3.5 gallons per minute (gpm) flow and 1100-1450 psi pressure. The importance of flow and pressure ratings will become evident later on in the "system design" section. The following charts list popular Saginaw P style pump applications, part numbers, and flow/pressure specs: |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

Saginaw "TC" Style pump This is like the model found on late model Jeeps (WJ, TJ etc) Some have an integrated reservoir, others often feature an externally mounted remote reservoir. They are generally capable of 2.4 - 2.8 gpm and 1350-1450 psi.

The following chart list popular Saginaw TC style pump applications, part numbers, and flow/pressure specs: |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

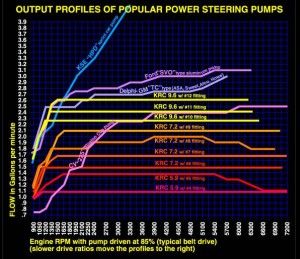

Aftermarket Pumps There are many companies manufacturing "aftermarket" power steering pumps. Many originate for the roundy-round crowd (auto racing). They vary from re-badged stock Saginaw pumps to extremely high end specialist pumps. I chose a pump from KRC. It's a completely new cast iron pump, no attached reservoir, comes with a 6" aluminium V-belt pulley (other configurations, such as serpentine belts available) , has -10 JIC (AN) inlet fitting and -6 JIC pressure outlet fitting, and has the ability to accept various flow control valves. I chose the largest flow valve available, and so the pump is rated at 1350-1450 psi and 3.7 gpm. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

This is the pump I chose. Here's what the manufacturer has to say about it. My impressions will be included in Part 3 of this article. KRC 50010 |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

This is what it looks like without a pulley. | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

Here's the Chevrolet "head mount" bracket kit I ordered with it. | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

And this is what the interchangeable flow valves look like. Stock, the pumps come with a 2.5 gpm valve. Additional valves from 1.5 to 3.7 gpm are available for about 12 bucks each. I bought the additional 3.7 gpm valve. | ||||||||||||||||||||||||||||||||||||||||||||||||||

It would take another entire article to really discuss pumps and pump technology - perhaps a future project. Just be sure that whatever pump you use, it must be in excellent condition to stand up to the rigours of running a hydro steering system. For now - here is some very good information taken from the FAQ at the GM F-body site, followed by some links where you can read more about pumps.

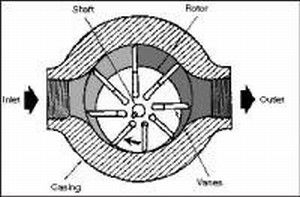

PS Pump links http://www.sandstruck.com/catalog2000/power/powersteeringsaginaw.htm http://www.woodwardsteering.com/ Steering unit The Steering unit is really the heart of the hydro steering system. It is the most specialized component, the one most people are least familiar with (we may already instinctively understand the principles of power steering pumps, and are familiar with hydraulic cylinders from applications such as presses and bottle jacks, but we may have little or no previous experience with any sort of rotary spool valve and metering unit. Small wonder then, that the steering unit is the most misunderstood and erroneously described part. Hopefully we'll fix all that here and now. I already harped on above about not calling it an "orbital valve", so I won't labour that point. There are a large number of different types of steering units available, each with a huge number of possible options, configurations and valving options. Some are of interest to us / useable for our needs, and some are not. They fall into the following 3 broad categories:

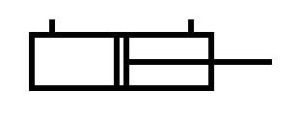

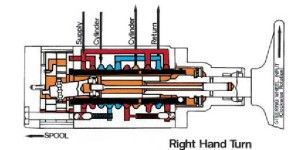

Each of which can further be subdivided into Load sensing or non-load sensing and load reaction or non-load reaction. Different manufacturers may have slightly different terms for each design, feature, or configuration. Be advised though, that load sensing and load reaction ARE NOT the same thing, although they are often mistakenly described as such. Steering unit design and function: The following description of the design and function of a hydraulic steering unit is taken from the Parker HGA Series Steering Unit Service Manual. However, the basics hold true for all steering units. For greater detail on how steering units work, see the manuals included at the end of this article, they include detailed service manuals with exploded diagrams etc. The hydraulic steering unit consists of a fluid control valve section and a fluid metering section which are hydraulically and mechanically inter-connected. CONTROL VALVE METERING SECTION POWER STEERING OPERATION |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

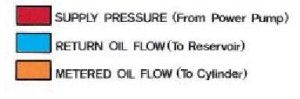

When referring to the pictures, use this colour code | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

Valve and metering function - Neutral position (no steering) | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

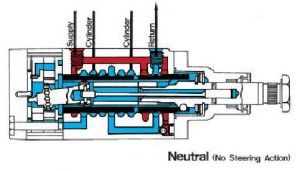

Valve and metering function - Left turn | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

Valve and metering function - Right turn | ||||||||||||||||||||||||||||||||||||||||||||||||||

In order to accomplish a power steering

manoeuvre, the operator must rotate the steering wheel in the direction of the

steering manoeuvre. The initial rotation of the steering wheel rotates the input

shaft which tends to rotate the drive link and rotor set through the MANUAL STEERING OPERATION Steering unit designs / options Open Center This is the type of steering unit of greatest interest to us. It is the simplest and most economical design, has all the features we typically need, and uses a fixed displacement pump. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

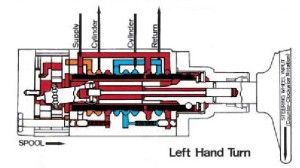

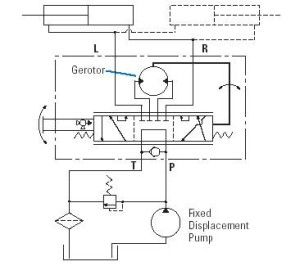

This is the hydraulic circuit diagram for a typical Open center hydro steering system. The objects at the top of the drawing are the steering cylinders. If you wish to fully understand the circuit, refer to the pdf of hydraulic circuit diagram symbols near the end of Basic Hydraulics |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

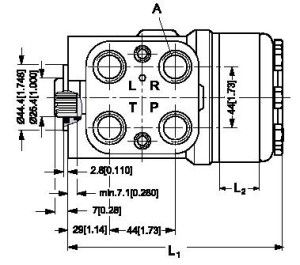

This is a schematic of a typical Open Center steering unit (this particular example is a Danfoss unit). Note the four (4) ports marked L,R,T and P. These are the four hydraulic fluid connection ports that make the unit operate. They are as follows: P - Pump. The high pressure input from the pump T - Tank. The low pressure return line to the reservoir (tank) L - Left. The high pressure output line to the left steering cylinder port i.e. when you turn the steering wheel to the left (counter-clockwise) this port carries fluid under pressure to the steering cylinder(s) R - Right. The high pressure output line to the right steering cylinder port i.e. when you turn the steering wheel to the right (clockwise) this port carries fluid under pressure to the steering cylinder(s) Note also the splined shaft on the left that is the operator input (the steering column connects here) |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

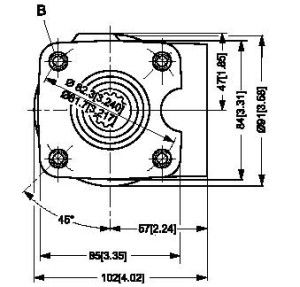

End view schematic of the steering unit showing the splined input shaft and the four mounting holes. | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

A Pic of my Performance Off-Road Systems Danfoss steering unit, ports up (to help release trapped air) , mounted to the firewall. | ||||||||||||||||||||||||||||||||||||||||||||||||||

Open Center Power beyond This system design is very like the Open center design described above, in that it is to be used with a fixed displacement pump. The difference is, this type of steering has an additional (fith) port on it that can supply fluid to auxiliary hydraulic valve functions. i.e. when fluid is not required for steering *the steering always takes precedence) it can be made available through the fith"power beyond (PB)" port for auxiliary functions like raising or lowering a blade or bucket. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

When not steering, the power beyond unit directs all inlet flow to the auxiliary circuit. However once steering is initiated, part of the auxiliary flow is diverted to steering. Since steering has priority, all flow, if required, will be diverted to steering. The tank port of the steering unit has flow only when steering is operated. Thus, flow out of the auxiliary (“PB”) port and the tank port will fluctuate or stop depending on steering input. | ||||||||||||||||||||||||||||||||||||||||||||||||||

The following special considerations should be addressed when applying power beyond steering:

Generally, there is no advantage to us in using an open center power beyond steering unit. But if that's all you have, it can be used successfully, and the PB port can even be blocked off if necessary. Closed center The closed center design is not suitable for our use, cannot be used with automotive power steering pumps, and is used on large construction equipment. In this system, a pump can rest when the oil is not required to operate a function. This means that the steering unit valve is closed in the center, stopping the flow of the oil from the pump. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

Closed Center systems use a pressure compensated variable displacement pump. In neutral position pump and tank are disconnected. Most suitable on large construction equipment. |

||||||||||||||||||||||||||||||||||||||||||||||||||

Load Sensing Let me get this out of the way right now. Load sensing has nothing to do with the wheels returning to center, or road feel through the steered wheels back to the operator. Many many people think that it does, but I'm afraid they are all wrong. Load sensing is a type of hydraulic circuit that is again, of little to no use or interest to us or our needs, but rather is for agricultural / construction / mining equipment and the like that use many hydraulic functions (blades, lifters, implements, etc.) The following description of load sensing circuits is taken from Eaton. More information for those interested is available in the various pdf catalogues and manuals available at the end of this part of the article , in the "resources" section. Load Sensing Circuits

Char-Lynn load sensing steering control units and priority valves can be used with open center, closed center or load sensing systems. Use in an open center system with a fixed displacement pump or a closed center system with a pressure compensated pump, offers many of the features of a load sensing system. Excess flow is available for auxiliary circuits. Listed below are the components of a typical load sensing control circuit and a brief application description.

Load Reaction THIS is the hydraulic circuit feature that is of interest to us. Load Reaction is the infamous "return to center" feature. Note however, that this feature only allows external forces on the wheels to cause a reaction in the steering wheel. That is, it is only permitting the transfer of force, not actually creating it. This means, how well the steered wheels will return to center after a turn will still very much be a factor of steering geometry / alignment - most notable caster. Without sufficient castor or proper geometry, even with a Load Reaction steering unit, "return to center" and road feel can still be very poor. On the other hand, with good geometry and alignment, and a Load Reaction steering unit, road feel and return to center can be excellent. Note: Some manufacturers refer to these functions as "reversing" and "non-reversing." Here's what Eaton says about it: |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

Non-Load Reaction A non-load reaction steering unit blocks the cylinder ports in neutral, holding the axle position whenever the operator releases the steering wheel. |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

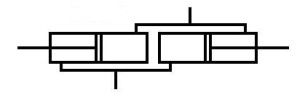

Load Reaction A load reaction steering unit couples the cylinder ports internally (in the neutral position) with the meter gear set. Axle forces are then allowed to return the steering wheel to its approximate original position. Comparable to automobile steering, gradually releasing the wheel mid turn will allow the steering wheel to spin back as the vehicle straightens. The cylinder system used with load reaction units must have equal oil volume displaced in both directions. The cylinders should be a parallel pair (as shown) or one double rod end unit. Do not use with a single unequal area cylinder system. |

||||||||||||||||||||||||||||||||||||||||||||||||||

Steering Unit Integral Valves If you recall how the steering unit is in fact a combination of valve(s) and metering unit, it will not be a surprise that there are often (depending on manufacturer) a number of "optional" valving functions available on steering units. Most are not really required by us, except for one very important one - the Manual Steering Check Valve. Most, if not every steering unit I have ever read about that we might possibly use includes one of these. It is a small valve built in to the steering unit that allows the steering unit to act as a small hand operated pump (by turning the steering wheel), providing limited manual steering, should the engine, pump or a belt quit. In my experience, the result is that the steering operates almost identically to normal automotive Saginaw power steering with no power. It is extremely difficult, if not impossible, to manually turn 38" tires at low pressure in a spooled and slugged front axle while sitting still with the engine off. However, with, say, a black YJ belonging to a good friend towing you along at a reasonable clip, it's actually quite steerable. I know this, because the first day I was testing my hydro steering I fried an alternator and a coil! Again, the experts at Eaton can tell you more about valving options on steering units (and again, there's plenty more info available in the pdf files at the end): Integral valves are available for the Char-Lynn® steering control unit. Included are: Inlet Relief Valve, Cylinder Port Shock Valves, LS-Relief Valve, and Anti-Cavitation Valves for cylinder ports. In addition, a Manual Steering Check Valve for limited manual steering is included. The integral valves eliminate the need for a separate valve block, and provides versatility to meet any steering circuit standard. Valve Description:

**Steering units with displacements larger than 185 cm3/r [11.3 in3/r] may require a separate power source for limited operation. Summary A hydraulic steering unit consists of a directional control valve and metering section. The valve directs the pressurized oil supplied to and from the cylinder and the metering section. The metering section “meters” out the pressurized oil to the steering cylinder. Open Center - pump and reservoir are connected when the steering unit is in the neutral position (not being steered). Requires fixed displacement pump. Open Center, Power Beyond (5-line)- The steering unit has an auxiliary fifth port as a Power Beyond feature to supply fluid to other functions downstream of the steering unit. The Hydraguide automatically takes priority flow for steering, with the remainder available for auxiliary functions. When not steering, all flow is available to auxiliary functions. Not really required for us, but useable. Closed Center - Closed center systems utilize a variable displacement pump providing variable flow to the steering circuit. All ports of the steering unit are blocked when the vehicle is not being steered. Of no use to us. Manual Emergency Steering—A ball check valve allows manual steering in emergencies when pump flow is interrupted. Non-load reactive (non-reversing)— The non-load reactive steering unit keeps the steered wheels in the steered position when the operator releases the steering wheel. The cylinder ports are blocked in the neutral valve position. The operator must steer the wheels back to the straight ahead position. Load reactive (reversing)—The load reactive steering unit allows the steered wheels to return to the straight ahead position after the operator releases the steering wheel. This happens only if the steering geometry exerts a centering force on the steering cylinder. The cylinder ports are interconnected with the metering section so that the steering wheel follows the wheels back to center position. Reversing steering units should only be used in systems where the opposing cylinder chambers are of equal volume. DO NOT USE with a single unequal area/volume cylinder. Steering Unit specifications Even once you have decided on a "type" of steering unit for your application (most likely an open canter, load reactive, non-load sensing unit) there are usually several options available in that type, depending on the specifications. There are a huge number of technical specification that describe a hydraulic steering unit, which is why they often have very specific 30 digit part numbers, from maximum system pressure, to flow requirement, to maximum permissible temperature differentials, to required ISO filtration levels and required input torque. It can get quite complicated, which is why ultimately it can be to your advantage to consult / source your components from a knowledgeable dealer like Performance Off-Road Systems. However, the important specifications for a steering unit are:

How each of these effects your steering performance can only really be fully understood in the context of all the other components of the system, like the pump and cylinder(s). This we will cover in the section on "System Design". However, a basic understanding of what the specifications are can be useful. Flow - this will normally be listed in 2 parts - maximum continuous rating, and recommended. The maximum continuous rating doesn't really concern us, since even the smallest lawn tractor mini steering unit is rated at 8 gpm, and recall most Saginaw steering pumps will be delivering 2-3 gpm and the highest performance pumps only 3-5 gpm. This would only become a concern if you were running some sort of industrial or agricultural pump capable of many gpm. Of interest to us is the recommended flow. This specifies the required flow the pump used must be able to generate to operate the steering unit FOR A GIVEN STEERING INPUT SPEED. In other words, a certain flow from the pump is required so that the steering wheel can be turned at a certain speed without loss of power assist. Normally, the industry standard steering input speed is two turns of the steering wheel per second. That means, if you see a steering unit rated at 3.43 gpm recommended, that steering unit requires a pump deliver at least 3.43 gpm so that you can turn the steering wheel at a rate of 2 turns per second (incidentally, this is a pretty darn fast rate - try it some time and see. It would be most unusual if you could rotate your steering wheel at a rate exceeding 2 full turns per second. 1 to 1.5 turns per second is a more normal input rate). In this example, if you were only able to supply this steering unit with 2 gpm, you would either have to reduce the rate at which you turn the steering wheel to something less than 2 turns per second (yes - in the "design" section we will cover how to calculate allowable steering speeds for given flow delivery), or, if you do turn the wheel at more than 2 turns per second while delivering less than 3.43 gpm you would experience a loss of power assist. Note also that how fast you want to be able to turn the steering wheel will depend a lot on how many turns lock to lock your steering system has (which is governed by the next steering unit spec - it's displacement). For example, if you use a low displacement steering unit so that your steering has 8 turns lock to lock, you would want to be able to turn the wheel faster (to navigate a fast twisty section, for example) than if you used a high displacement steering unit so that you only has 2 turns lock to lock. Displacement - This spec is the volume of fluid that is metered to the cylinder per revolution of the steering unit. It is normally specified in cubic inches per revolution (cu.in./rev). It is important because it, along with the dimensions of the cylinder (volume) will determine at what rate the cylinder extends and retracts; which translates into how many turns of the steering wheel it takes to go from lock to lock. Again, we will discuss the exact calculations in the design section. For know - if steering unit displacement is to small (in relation to the cylinder specs), the steering will seem slow and unresponsive. If it is too great, the steering will be twitchy and hard to control. Pressure - This spec will be listed as a maximum operating pressure. It must be greater than the maximum pressure the pump is capable of, or component damage may result. Values in the 1800-2500 psi range are common. When compared to the common 12-1500 psi of automotive power steering pumps, again, there shouldn't be a problem for us. However, some steering units are rated at <1000 psi so care must be taken. Steering column |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

The steering column is one of the more simple parts of the steering system. It bolts directly to the steering unit on one end, and then either directly to the steering wheel (as shown in the pic at left) on the other end; or can be connected to a further steering shaft that connects to the steering wheel. It simply provides a means for the operator to control the steering unit and therefore steer the vehicle. I much prefer the idea of connecting the end of the steering shaft to a regular steering shaft and thence to the steering wheel, rather than directly to the steering heel. While adding additional parts and complexity, I feel that this is well worth it as it allows the steering unit to be located outside the drivers compartment, on the other side of the fire wall. This keeps the high pressure hoses away from the driver compartment and minimizes the chance of a dangerous fluid injection accident in the event of a hose failure or rupture. |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

This is my Performance Off-Road Systems steering column, that Performance Off-Road Systems has custom made with a 3/4-36 spline en d.. Normally, the "steering wheel" end of the shaft is provided with both a threaded end and nut, as well as a splined section to facilitate a number of different options for mounting the steering wheel or an intermediate shaft. | ||||||||||||||||||||||||||||||||||||||||||||||||||

There are a quite a few different

sizes and configurations commonly available, such as

Splines:

The most common size is the 36 spline .875" as this is a common agricultural size. You will notice though, that despite these many options, 36 spline .750" is not one of them. This is a shame, as 36/.750 is the common automotive steering shaft spline size. That's one of the great things about the Performance Off-Road Systems shaft - it comes custom made to fit standard automotive parts, as opposed to some other companies that supply the agriculture size parts that send you searching for agricultural parts to match. Cylinders In the world of hydraulics, there is an unbelievable number of different actuating cylinders - from telescoping rams to single acting spring-loaded piston actuators to three port double actuating cylinders. Fortunately very few are of interest to us, and also fortunately those that are of interest are not too complicated to understand. Before continuing I do recommend that you return to Part 1 and just review the section on actuators. OK, so I know most of you probably wont, so here's a quick pic of some terms, and remember....the cylinders we use are not rams! :-) |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

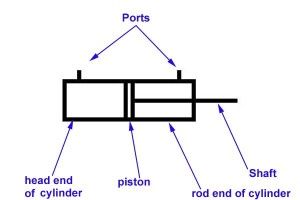

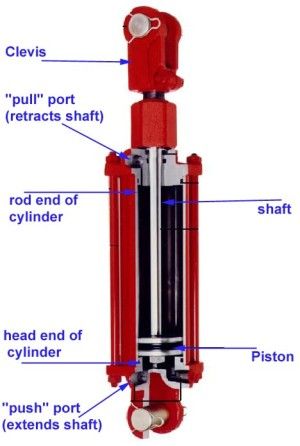

Diagrammatic representation of cylinder parts - this is a common unbalanced cylinder. | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

An agricultural tie-rod cylinder. | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

Labelled cutaway diagram of the same unbalanced common agricultural tie rod cylinder. | ||||||||||||||||||||||||||||||||||||||||||||||||||

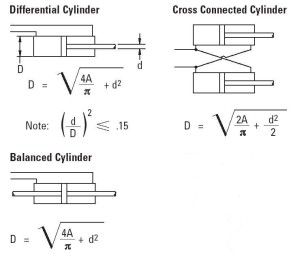

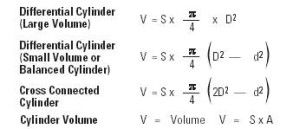

All cylinders of use to us are piston-type cylinders. A piston-type cylinder is an actuating cylinder in which the cross sectional area of the piston is less than one-half the cross-sectional area of the movable element . This type of cylinder is normally used for applications that require both push and pull functions. This makes sense, since we will need to both push and pull as we steer both the tires from left to right and back There are 3 basic designs of piston-type cylinders. They are: Single acting - The single-acting piston-type cylinder uses fluid pressure to provide the force in one direction, and spring tension, gravity, compressed air, or nitrogen is used to provide the force in the opposite direction. This design is of no use to us. Tandem Cylinder - A tandem actuating cylinder consists of two or more cylinders arranged one behind the other but designed as a single unit . This design could be used for hydro steering, though I have personally never seen it. Double acting - Most piston-type actuating cylinders are double-acting, which means that fluid under pressure can be applied to either side of the piston to apply force and provide movement. The two fluid ports, one near each end of the cylinder, alternate as inlet and outlet ports, depending on the direction of flow from the steering unit. All of the hydro steering systems I have ever seen or researched use some sort of double-acting, piston-type cylinder. Double-acting cylinders can be further broken down into balanced (often called "double ended") and unbalanced (often called single ended) types, and there are two possible configurations for steering systems using unbalanced cylinders - namely two (2) cross connected cylinders or one (1) differential cylinder. I prefer to use the terms balanced and unbalanced as they have meaning in the hydraulic industry. The terms "single ended" and "double ended' do not, as obviously, any cylinder will have 2 "ends", making it "double ended", it's just that both "ends" may not have pistons extending. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

Balanced double-acting piston-type hydraulic cylinder The actuating cylinder shown at left is a double-acting balanced type. The piston rod extends through the piston and out through both ends of the cylinder. In a hydro steering system both ends of the piston rod will likely be attached to a mechanism to be operated. i.e. the steering arms on the knuckles. The cylinder provides equal areas on each side of the piston. Therefore, the same amount of fluid and force is used to move the piston a certain distance in either direction. This means that in a hydro steering setup, use of the balanced cylinder results in equal steering speed, effort, and number of turns to lock whether turning left or right. This fact, and the units compact design makes it by far the best choice for a hydro steering system. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

Pic courtesy USFSIHC |

Unbalanced double-acting piston-type hydraulic cylinder. This cylinder is referred to as an unbalanced actuating cylinder because there is a difference in the effective working areas on the two sides of the piston, because of the area consumed by the shaft where it attaches to the piston and where it reduces the volume inside the rod end of the cylinder. Therefore, this type of cylinder is normally installed so that the blank side of the piston (the side on the left in this pic) carries the greater load; that is, the cylinder carries the greater load during the piston rod extension stroke. A four-way directional control valve (like a steering unit) is normally used to control the operation of this type of cylinder. The valve can be positioned to direct fluid under pressure to either end of the cylinder and allow the displaced fluid to flow from the opposite end of the cylinder through the control valve to the return line in the hydraulic system. Despite the fact that running a cylinder of this type will result in an uneven steering speed and number of turns to lock whether turning left or right, it is a very common setup. It does have the advantage of low cost, less weight (usually) and easy availability of suitable cylinders. The biggest drawback to this setup, is in my opinion, the fact that it requires an additional solid mechanical tie-rod (linkage mechanically joining 2 steering knuckles). In effect, where a balanced cylinder replaces the drag-link and tie-rod of conventional steering, the single unbalanced cylinder replaces just the drag-link. The problem really is, it can be a real challenge to mount the single unbalanced cylinder AND the mechanical tie rod in perfect (or even acceptable) geometry. WAY too often I see systems where the cylinder applies force to some component, usually the tie-rod itself, in a manner that produces fatigue and weakening in the part. The hydro cylinder is extremely powerful, and will usually have its way with whatever it is attached to. If you don't get it's force applied in a linear fashion - it will introduce bending forces on the part, which is an extremely bad idea in a steering system. That said, with careful attention to geometry, it can be made to work well, as the pic of USFSIHC's setup at left shows. |

||||||||||||||||||||||||||||||||||||||||||||||||||

Two Unbalanced, cross-connected double-acting piston-type hydraulic cylinders. This is system that is fairly common on large construction, industrial, mining, etc. equipment, but is seldom seen in use on a 4x4. By using 2 cross-connected unbalanced cylinders, the drawbacks to the single unbalanced cylinder setup can be eliminated. By cross-connecting the cylinders in parallel, one is extending while the other is retracting, and equal steering speed, force, and turns to lock will be experienced whether steering right or left. However, because the two unbalanced cylinders are separate units, not mechanically linked (as the ends of the balanced cylinder are), it means that the 2 steering knuckles would have no mechanical connection unless a separate mechanical tie rod was also used. The problem with this is, either another separate mechanical tie rod must be used (as in the pic to the left) with the attendant increase in weight, number of parts, complexity of fitment and space used; OR if no separate mechanical tie rod is used, the only way to set alignment would be hydraulically and the cylinders could not be cross connected. Cross-connecting the 2 unbalanced cylinders with no additional mechanical tie rod would cause the tire with the least resistance to steer, and the other one not to steer at all. In summary, this setup can be used effectively, and is on larger equipment, but the bulk and weight of the system makes it impractical for 4x4 use. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

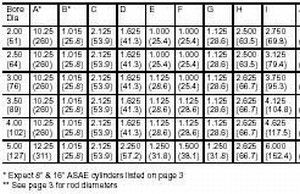

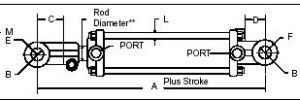

Cylinder Specs. As with steering units, Once you have selected a particular type of cylinder, how to determine your steering system's requirements in terms of the cylinder specs will be covered in detain in the "system design" section. We will cover here the basics of cylinder specifications. Again, there are quite a few specification to call out a specific cylinder, including weight, extended and retracted lengths, material, port sizes etc. The most important cylinder specifications are

Bore - The bore of the cylinder is also the size of the piston. Recall from Part 1, that the cylinder works by means of pressurized fluid acting on the cylinder piston. The bore is often specified in terms of its diameter, but it is its area that is most useful. From simple geometry, we know that from diameter we can calculate area as A=pi(d/2)^2. With area, and simple algebra, we can multiply the pressure of the fluid (as dictated by the pump/relief valve) by the area of the piston, and we have the force the cylinder can exert in pounds. This is the "power" of the steering system. Note - with an unbalanced cylinder, this is valid only for the head end of the cylinder, i.e. the force calculated is that with which the shaft extends (called "push"). What this means, is that the steering force, or "power" is greater in one direction (whichever steered direction is when the shaft extends) than the other. This is because when the shaft retracts (called "pull") the fluid is acting against a reduced area, since the shaft area deducts from the available piston area upon which the fluid is able to act. To calculate pull, multiply pressure by (bore area - shaft area). With a balanced cylinder, pull is always equal to push, since when one side is extending, the other is retracting and the piston areas are equal (see pic above). If you look at the diagram of the two cross-connected unbalanced cylinders above, you will see that this arrangement also allows pull to equal push, so that steering force in either direction is equal. Shaft size (diameter) - As described above, shaft diameter (and therefore area) plays a part in how much force a cylinder can generate, and this is true for both balanced and unbalanced cylinders. Counter-intuitively, for a given bore size cylinder, the larger the shaft dia, the less force it is able to generate. Shaft size, in relation to bore size is also a factor in the volume of the cylinder, as described below. Finally, the size of the shaft has a direct effect on how rugged the cylinder is, and what sort of side loads and abuse it is capable of handling. Stroke - The stroke, or "throw" of the cylinder, along with the length of the steering arm (measured from kingpin/balljoint to where the cylinder shaft attaches) describes how much steering motion the system is capable of, i.e. how far it can steer the wheels left and right. If the stroke is longer than the knuckles can accommodate, and the steering force is high enough, you risk damaging the knuckles or even breaking them right off the axle. If the stroke is too short, you will not be able to fully steer left and right all the way. Swept Volume - The bore x stroke of the cylinder describes the swept volume of the head end of an unbalanced cylinder, and the bore area - rod area x stroke describes the swept volume of the rod end of an unbalanced cylinder, or either end of a balanced cylinder. The swept volume of a cylinder, in relation to the displacement of the steering unit, describes how many turns lock to lock the system will have. Here's a table that summarizes the HYDRAULIC effects of the different cylinder specs, assuming ALL OTHER specs, and system components (like pump working pressure, steering unit displacement, etc.) remain constant. Notice, I emphasized that the table shows hydraulic effects. I haven't included the mechanical effects, as they should be obvious - for example, increasing shaft diameter makes for a more robust cylinder, increasing bore makes for a larger cylinder, requiring more room to mount etc.

Of course, the kicker is, all other specs do not remain the same (or at least, they don't have to) so we again see that system performance depends on a complicated inter-relationship between many factors - you cannot simply change one thing and always predict the outcome without re-calculating the other system variables. For example, for a given amount of force (steering power) required, cylinder bore can be traded against system working pressure, but only to the extent that the pump and/or relief valves allow. On the other hand, you can trade pressure for cylinder bore, but of course this (changing bore size) will affect not only the power, but also either the number of turns lock to lock of the system, or if it is desired to hold number of turns to lock constant - the required displacement of the steering unit is altered. The best way to understand this is to become familiar with / use the online calculator/spreadsheet/equations in the "system design" section. Of course, even that is not perfect, as although the force requirements derived by formula are theoretically correct, other factors must be considered. One factor is pressure drop. Working pressure at the cylinder port will be less than at the pump outlet. This should be allowed for in your calculations. A margin for overcoming friction in the cylinder must also be added. In addition, a certain amount of force exerted by a cylinder is counteracted by friction developed through the seals and, to a lesser extent, by the weight of the piston itself. If, however, at this point you just scroll to the bottom of this page for the phone number of Sean at Performance Offroad Systems, then call him up and say "Billavista said you'd set me up" - I can't blame you !! :-) Basic cylinder equations: The force a cylinder can generate is equal to the product of the piston area (sq. in.) and the pressure (psi), minus losses due to inefficiencies (friction, pressure drop, etc) F=A*P*e where: F- Force (pounds) A = Piston Area (sq. in.) P = pressure difference across cylinder ports (psi) e = cylinder hydraulic/mechanical efficiency (0.85-0.95) You can re-write the equation algebraically to calculate the area required of a piston (the bore of the cylinder) if you know the required force: A = F/(P*e)

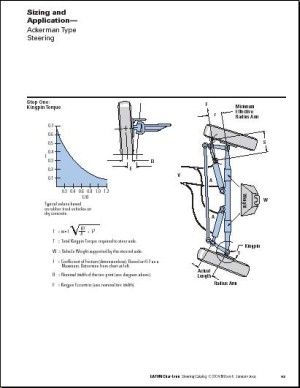

System design Ok, here we are. Finally. Now that we have a good grip on the fundamentals, the physics, the language, we can finally discuss the design of a hydraulic steering system, or "how to select the right components for your system". Remember, the key to being successful here is understanding how interconnected all the system variables are. From pump flow capacity to system pressure to the displacement of the steering unit and the bore and stroke of the cylinder used, all the system components and their specifications must work together and be properly balanced and matched. The design process outlined below is taken largely from the system design and component sizing information provided by Eaton/Char-Lynn and Parker/Ross in their hydraulic steering component catalogues, combined with some interpretation on my part and influenced by my personal practical experience. For ease of reference and printing I combined the applicable design pages from each of their catalogues into a single pdf file on: Hydraulic Steering System Design and Component Sizing The design process outlined is a step by step process, from beginning to end. However, I am completely aware that very few people will actually undertake this from start to end as outlined. Far more likely is that you already have a steering unit and are wondering what size cylinder to use with it, or you are wondering if your pump will suit your system, or you have a complete system installed and you're not happy with it, so you are curious as to the effects of altering certain components. I understand this, and in an effort to help, have also developed a Microsoft Excel spreadsheet that will make the calculations for you on the fly. It isn't as detailed or well described as the table below, but it is useful in that you can change variables on the fly and see what the effects are. Other than that, the equations given and explanation should allow you to understand the whole process enough to calculate exactly what you need to know, no matter what your exact system parameters are, or where you "enter the process". One final note - there are those that would criticize or disagree with the model explained in steps 1-4 that arrives at a Kingpin Torque figure (basically, a measurement of how much steering effort, or power is required for the given vehicle). As noted, the model is based heavily on the industrial / agricultural hydro steering requirement model designed by Eaton and Parker. We know that our situation is not exactly the same as that of a tractor or mining truck, and so there is the potential that the model will provide a dissatisfactory result. Personally, I think it does a pretty darn good job, and is certainly the best method of which I am aware, but of course I make no guarantee of fitness. Most importantly - the following information should serve to clearly illustrate how all of the variables are heavily interrelated, so that we may indersatnd how pressure and bore size and stroke etc. all work together. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

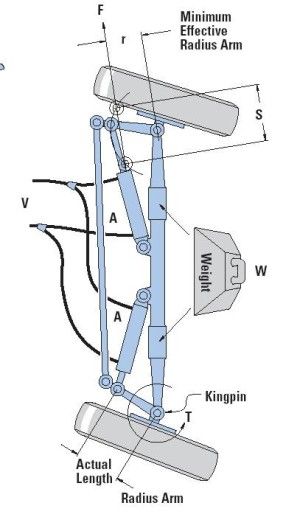

|

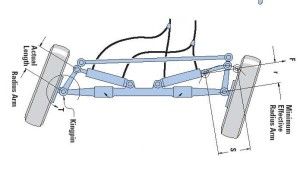

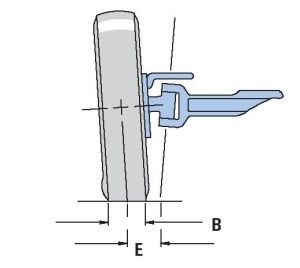

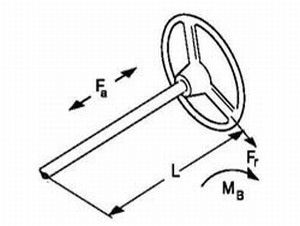

Step 1 - Measure tire / steering geometry: E = Kingpin Eccentric (offset) (inches) B = Nominal width of the tire print (inches) |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

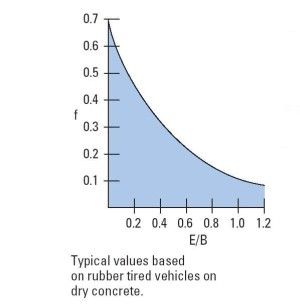

Step 2 - Calculate the Coefficient of friction (f) (dimensionless) Taken from the chart on the left. Enter the chart at the horizontal axis with the value of E/B (from the measurements taken in step 1) and draw a line up until you reach the line separating blue from white. Then draw horizontally across to the vertical axis and read of the value of (f) |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

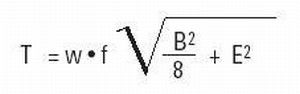

Step 3 - Calculate Total Kingpin Torque required to steer axle (in/lbs). T = Total Kingpin Torque required

to steer axle (in/lbs). |

||||||||||||||||||||||||||||||||||||||||||||||||||

Step 4 - Determine drive factor (D) and re-calculate Total Kingpin Torque The drive factor (D) is a multiplication factor of my own design. It is based on the fact that the manufacturer's recommend doubling the kingpin torque for vehicles where the steered axle is powered (driven) in order to approximate the additional dynamic loads. Where our requirements are somewhat unique and, as yet, unaccounted for by the manufacturers, I am suggesting this "drive factor" as a possible way to account for and include the unique demands of a hardcore off-road 4x4s steering, particularly in rock-crawling applications. As such, I propose the following: Allow a drive factor (D) of -

Re-calculate the Total Kingpin Torque as KT = T x D |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

Step 5 -

Calculate Force Required from the hydraulic cylinder (F) (lbs) F =KT/r where:

note that in the diagram depicting r, a single unbalanced cylinder is shown, but the same is true for a balanced cylinder. |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

Step 6 - Determine steering system pressure (P) (psi). This will most likely be determined by the limitations or capability of the pump (or more accurately, the internal bypass relief valve setting in an automotive power steering pump). However, the figure used must be as accurate and honest as possible (there's no point kidding yourself that your 20 year old junkyard pump is running at 1500 psi) and must also account for system losses leading to pressure drop (primarily frictional losses). Usually, use 80-95% of the steering pump or circuits relief valve setting. e.g. if my power steering pump is advertised at 1400-1500 psi. I may elect to use a figure between 1100 and 1400 psi |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

Step 7 - Calculate required cylinder area for the system to generate the required force (A) (sq. in.) A = F / P where: A = required cylinder area (sq in) F = force from step 5 (pounds) P = pressure from step 6 (psi) |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

Step 8 - Determine the arrangement of cylinders to be used. Refer to the section on cylinders above and in part 1, and decide which style you wish to use. Alternatively, you can make the remaining calculations for all 3 styles, and compare the results. Or, you can just choose a balanced cylinder, as it is by far the best solution (in my opinion). |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

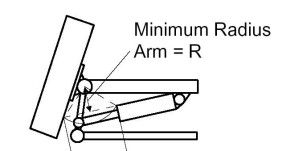

Step 9 - Calculate required cylinder bore diameter (D) (in) Once the required cylinder

set area is determined, the cylinder diameter can be calculated. Hydraulic cylinders are specified by "bore", which is the diameter of the piston. Therefore, to know what cylinder we need, we calculate the bore from the area calculated in step 7. However, if you recall from the section on cylinders, because of the shaft, and especially in the case of unbalanced cylinders, it isn't as simple as just calculating from A=(pi)r^2. The diagram at left shows how to calculate the bore for each of the 3 different cylinder arrangements. Note that it calls the unbalanced cylinder a "differential cylinder" Once D is calculated mathematically, select the next larger common cylinder bore size available. |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

Step 10 - Determine the required cylinder stroke (S) (in) The cylinder stroke is determined by axle geometry. That is, the required stroke is a function of the radius arm (steering arm) and the total angle through which the arm turns. An easy way to calculate it requires at least some kind of temporary fixed toe rod between the steered wheels. With this in place, turn the wheels by hand to full left turn. Make an indexing mark on the axle housing and the tie rod in the same place. Now turn the wheels to full right lock and measure the difference between the marks. This measurement is your stroke (S). Your choices will be somewhat limited by common availability. Strokes in the range of 6"-9" are common on 4x4 steering systems. |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

Step 11 - calculate the swept volume (V) of the cylinder(s) to be used Note that a single unbalanced (differential) cylinder will have a large volume (called the head end volume) and a small volume (called the rod end volume) because of the volume the shaft itself occupies. This difference in volume is what causes the different speed / number of turns to lock one way compared to the other (left compared to right or vice versa - depending on which way round the cylinder is mounted). Since the smaller volume will fill faster, steering speed to this side will be greater, meaning the number of turns to lock will be less and the steering force will be less (because of the reduced piston area for the fluid to act on - as seen in step 9.) |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

Step 12 - Decide on the approximate number of turns lock-to-lock desired. Depending on vehicle usage - street driven, trail only, rocks, mud, etc. and personal preference / driving style this number will vary - usually from about 2 to 6, with 4 being a reasonable value for street/high speed driven rigs and 2-3 for dedicated trail/rock rigs. |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

Step 13 - Calculate the required displacement of the steering unit per revolution in order to achieve the desired # turns lock-to-lock (DP) (cu. in / rev.) DP = V / N where: V = Swept Volume of full stroke from step 10 (cu. in.) N = number of steering wheel revolutions lock to lock Note: If using a a single unbalanced cylinder, this value will have to be calculated for both head and rod sides of the cylinder, and a decision made as to which to satisfy, leaving the other side with either more or less turns to lock than desired. |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

Step 14 - Select steering unit from those available, note actual displacement, and re-calculate actual number of turns lock-to-lock. Because step 13 may yield a number not actually specified by any manufacturer it is necessary to select the closest possible displacement, and re-calculate the actual number of turns lock-to-lock the system will have. N = V / DP where: N = number of steering wheel revolutions lock-to-lock V = Swept Volume of full stroke from step 10 (cu. in.) DP = actual displacement of steering unit (cu. in. / rev.) Again, note that this figure will differ between left to right is a single unbalanced cylinder is used. |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

Step 15 - Determine maximum required steering input speed (SS) (rev. / sec.) You must determine how fast the driver must be able to turn the steering wheel and still have full steering power (if the driver turns the wheel faster than this, a dramatic increase in steering effort is felt as the power assist of the hydraulic fluid is unable to keep up) The minimum normally considered is 1 rev/sec (60 rpm). This depends on the safety considerations for avoidance of obstacles under minimum and maximum flow conditions during all speed possibilities of the vehicle. 1.5 rev/sec (90 rpm) is common, and 2 rev/sec (120 rpm) is considered about the maximum input speed achievable by an average person (go ahead and try and turn your steering wheel faster than 2 revolutions per second and get back to me if you can :-) It is important to take into consideration the number of turns lock-to-lock calculated in step 14. This is because what you really want to determine is how quickly you can turn the wheels lock-to-lock. For example, if you have 4 turns lock-to-lock (average) and wish to be able to steer the vehicle fast (2 rev / sec.) what you are really wanting is to be able to steer lock-to-lock in 2 seconds: 4 turns L-L / (2 turns/sec) = Lock-lock in 2 seconds Therefore, you can achieve the same steering speed with 2 turns lock-to-lock and a steering input speed of 1 rev. / second. |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

Step 16 - Calculate required pump flow. (QP) (gallons per minute) QP = SS x DP x 60 / 231 where: QP = required flow of pump (gpm) SS = steering speed (rev. / sec.) DP = Steering unit displacement (cu. in. / sec.) Note: When using an open-center steering unit connected with pump directly, maximum pump flow should be less than 1.4 times the steering unit rated flow. Higher flow into steering unit increases pressure-loss of the steering system. This step is probably the most likely entry point for those reverse-engineering a system, as the limiting factor is likely to be the pump used. That is to say, it's not as if there are suitable pumps available with an infinite range of flow rates. It should not be too hard to take the flow rate of your pump, and reverse the equations to calculate what sort of steering speed, number of turns lock to lock, size of cylinder to use, and steering force are supportable. The other option is to use the excel spreadsheet below and keep tweaking all the variables until satisfied. |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

Microsoft Excel File - System Design calculator | ||||||||||||||||||||||||||||||||||||||||||||||||||

Now Available: On-line Java System Design Calculator. Hydro Steering FAQ Q: Where can I get the parts? A: Easy one. Contact: Sean

Stapley 1712 Indian Pines Rd. Wetumpka , Al 36093 Phone: 334 567 7229 Fax: 334 567 7220 Q: Is it road legal? A: This will likely depend on your state/provincial and local authorities interpretation. According to my sources, the US DOT in Washington DC state: "There are NO safety standards issued for steering systems" Q: Is it road-safe? A: The answer to this one is the same as for most other "modifications". In other words, it can be, if done right. Now, you will hear all manner of people going on about "no mechanical linkage" and "no backup" and such. Most of these people don't have a clue how it works. There is also a huge knee-jerk reaction claiming it is patently unsafe and unfit at speed and not road-worth, simply because it is hydraulic, and people don't understand hydraulics, and so they think it m=somehow means certain death. I have long found this curious, as people will tool down the road with huge tires and woefully undersize and/or incredibly poorly engineered steering setups, and nobody flinches. On the other hand there are literally hundreds of machines that rely totally on hydraulics with no backups - from mining trucks to aircraft flight controls to the steering gear on massive ocean liners to cranes lifting huge weights...the whole idea that hydraulics are somehow more risky than mechanicals is absolutely ludicrous. Q: When the engine stalls or the pump fails, is it possible to turn with hydro steering ? A: Yes, with most steering control units. There is a small check valve in the steering unit that acts as a pump and will supply enough fluid to the cylinder for limited manual steering in emergencies. The effect is very similar to standard power-steering with the engine off - i.e. with big tires at low pressure and locked axles it is VERY hard to steer, but it can be done, and if rolling at a good speed, isn't too too bad. Q: What fluid should I use? A: Power steering fluid, ATF, or a good quality anti-wear hydraulic oil. If unsure, check the recommendations of the company manufacturing your steering unit. Q: How big of a reservoir should I run? A: As big as you possibly can. In industrial applications, the standard spec is 2X the gpm of the pump. that translates to about a 4+ gallon reservoir for the pumps we use. Most are actually running only about 2 quart reservoirs. Personally, I think a lot of the problems people have with hydraulic steering setups are related to inadequate reservoir size. You can't have too big of a reservoir. Q: Should I run the system vented or sealed? A: All industrial, agricultural, and heavy-duty hydraulic system setups, including steering, are vented to allow for the expansion of fluid throughout the significant temperature range experienced. If spillage is a concern, a diaphragm system should be engineered (similar to a brake master cylinder) Q: What pressure and flow are the stock Saginaw power steering pumps? A: See the section on pumps. Q: Is a stock pump enough for full hydro? How about for full hydro and hydroboost brakes? A: There are several users reporting satisfactory results with simple stock-type Saginaw pumps, even some running hydroboost brakes. Of course, as you now know, this will depend somewhat on the bore and stroke of the cylinder used, the displacement of the steering unit, and how many turns lock-lock are desired as well as maximum steering input speed desired. Refer to the section on system design. For my own personal experience - see Part 3 of this series. Q: What's the best way to hook it up to a stock steering shaft? A: Buy your system from Sean at Performance Offroad Systems, as he supplies a hydraulic steering input shaft that accepts the automotive standard steering shaft female spline. Otherwise, you will have to cobble something together from agricultural parts. Q: Can you run standard automotive TRE's with a hydraulic cylinder, instead of heim joints? A: Yes, you can. Especially if you deal with Performance Off-Road Systems as they will custom machine the cylinder for your needs. Q: Is there any "road feel" to hydraulic steering? A: Yes, there certainly can be, depending on the steering unit used, and it's internal valving options Q: Can a hydro steering system "return to center"? A: Yes, as long as a "reversing" or "load reactive" steering unit is used. References |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|