|

42" Pitbull Rockers By Bill "BillaVista" Ansell |

IntroductionI wasn't particularly looking for new tires - I thought I was happy with what I had. So when Mike at Pitbull Tires contacted me to talk about the new 42" Pitbull Rocker I wasn't sure what to expect. We talked about the tires and before you knew it I was changing tires the night before a 12-hour trip to the biggest event of the year. It was a bit of a gamble - after all we were off to the inaugural Virginia Tech Memorial Ride at Big Dogs Offroad where the plan was to run with XRRA / WE Rock / KOH competitor Doug Bigelow and his competition moonbuggy - I did not want to get left behind! Did the gamble pay off? Read on and see - here are the details: |

|

|

Mike shipped the tires exactly when he said he would - no muss, no fuss. That may not sound like a big deal, but you'd be surprised how many industry folks promise all sorts of things and end up falling a little (or a lot) short! As I was on a ridiculously tight deadline I appreciated Mike's efforts and have found that you can tell a lot about a company and how it treats its customers from how they follow through on their agreements. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

Happiness is a truck-load of new tires! | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

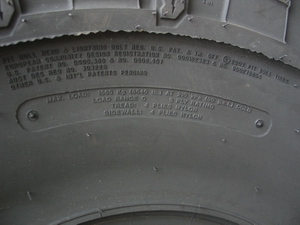

Just like the label says the 42 x 15.0-16.5 LT are a Load Range C (6-ply rated) bias-ply tire. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

The tread on the Rockers is unique and really aggressive. | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

There are many different shaped lugs... | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

...plenty of large voids... | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

... and tons of biting edges, some of them unlike anything I've seen before. | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

Many of the tread blocks also have built-in siping. | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Rockers also have a really beefy and aggressive shoulder / sidewall tread. | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

And they have lightning bolts too! | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

Rockers! | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

Unmounted tire. | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

And of course they have Pitbulls! Pitbulls and lightning bolts - cool! |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

Even the tread-wear indicators are unique... | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

... nothing, and I mean nothing, on these tires is like anything I'd seen before. | |||||||||||||||||||||||||||||||||||||||||||||||||||

Specs and DimensionsSo they have plenty of unique and cool-looking features, but how would they perform? Before we get to the performance, a few more dimensions and pics for your info / pleasure. |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

MMMMM........tires! |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

The 42 x 15.0-16.5 LT Rockers have a max load rating of 3640lbs at 30psi cold. That's nearly a 1000lbs more than some competitive brands!! They are bias-ply construction with the tread and sidewall both constructed from 4 plies of nylon. They weigh approx. 98lbs each. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

The specified rim width for the 42 x 15's is 12-14" | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

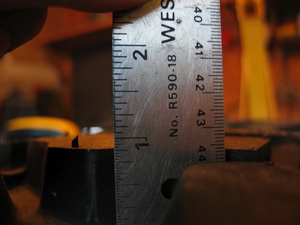

The tread depth on the 42's is about 29/32" | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

Here a 42 x 15 -16.5 is mounted on a 16.5 x 8.25 inch rim, inflated to 30psi and measured. | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

As you can see, they come in at 41.75", which is closer to the nominal height on the sidewall (42") than any other tire I've seen. | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

Compared to the same (nominal) size tire of a competitor the Pitbull Rockers are slightly lighter, slightly narrower, and slightly taller. The comparison is made unmounted as the width of the rim and air pressure used will affect the tire's mounted dimensions. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

The beads are a massive 3/4" thick and the sidewalls nearly 1/2" thick. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

TEAR IT UP Technology™ is Pitbull's term for for the proprietary construction/rubber design used in their tires which is said to be the secret as to why their tires are so cut resistant, puncture resistant and heat resistant. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

FANG Technology™ is Pitbull's term for the sidewall traction built into the Rockers. | |||||||||||||||||||||||||||||||||||||||||||||||||||

A few more pics of the new, unmounted tires:

And some pics of my buggy with the new tires mounted

Pics of various pressures. The following pics illustrate the right-rear tire of my buggy at various tire pressures with the tires newly installed. |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

30 psi | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

15 psi | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

10 psi | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

5 psi | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

2.5 psi | |||||||||||||||||||||||||||||||||||||||||||||||||||

PerformanceFinally, the most important part - and boy was I amazed! Talk about trial by fire - the first time I ran the tires was at the inaugural Virginia Tech Memorial Ride at Big Dogs Offroad. Running with XRRA / WE Rock / KOH competitor Doug Bigelow and his competition moonbuggy, in two days we ran every hardcore trail in the park. We just kept lining them up and knocking them down, one after the other. In two days we did about 6-months worth of hardcore rock crawling and trail riding! Shod with the Pitbull Rockers I conquered everything with confidence. I was extremely pleased with how well they flexed and stuck to the rocks, allowing me to stick a line. I even managed a line in the infamous "Bunny Trail" that Doug said had never been done before - you'll see this in the video. One thing that really stuck out was how well the tires would heat up and stick compared to other tires I've run. For example, when climbing a steep, rocky trail you know how sometimes you'll just fetch up on something a little and stop progress? At that point I'm used to having to back down and try again or pick a different line. This weekend with the Rockers was different. I decided to just stay on it, and sure enough, time and again, the tires would heat up, stick, and I'd just keep going forward - it was awesome! You can see an example of this in the vide at about minute 5:30. How do I know it wasn't just a fluke or the placebo affect of having new tires? That was the neatest thing - unlike others, I could smell the tires working - when they would heat up I could smell it and you could see it on the rocks afterwards as well. And the thing is, I didn't have to redline the motor for 5 minutes to get them to stick - just a little spin and we stuck and went - it was very cool. Thanks to Adrian and Andrew, there's some good video of the tires working - it speaks for itself. Keep in mind as you watch it that my barn-built 4-seat 10-year-old pig of a family wagon followed Bigelow in his comp-tire moonbuggy everywhere he went that weekend. Here's the video followed by some stills taken from it:

And a few stills from the video. Click to enlarge and check out the tires grabbing the rocks!

But the dry grippy rock of Big Dogs isn't the only place the Rockers worked well. I also took them to a local offroad park in Quebec called PJF Parc. PJF is infamous for big, wet, slippery rocks and plenty of mud, goo, and running water to challenge your grip. Once again, the Rockers were in their element, never letting me down, weather flinging gobs of sticky mud or somehow finding grip on the slippery rocks. Here are a few pics of the action:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

After a good beating on over a dozen hardcore trails the Pitbull Rockers have earned their place as my new favorite tire.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

They've held up well with no rips, tears, punctures, or big chunks missing. | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

They do show some wear on the lugs of course, but that is to be expected and is just more proof positive that the tires flex, work, heat, stick and grip better than any other I've run. | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

Man, I love these tires!!! | |||||||||||||||||||||||||||||||||||||||||||||||||||

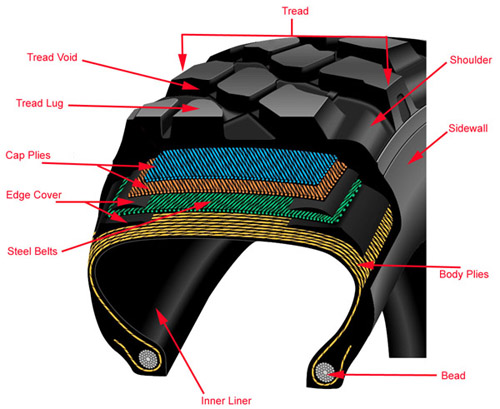

Basic Tire Tech To conclude, I'm including some basic tire tech and an examination of why bias-ply tires are still my personal choice for serious offroad duty. What is a tire and what does it do? On the face of it, it's quite simple. A tire is just a rubber air bladder that contains pressurized air to support the vehicle's weight, right? Well, yes...but it also transmits acceleration, braking, and cornering forces to the road or trail, and acts as a spring between the trail and the wheel. It's able to do all this because of the way it's constructed. You see, a tire isn't just a rubber balloon - it has a carcass made of plies (or layers) that give it shape, strength, and stability (otherwise when filled with air it would just expand in a wobbly and uselessly round fashion like a balloon tire in a kid's picture). It has a steel bead to clamp it to the rim with sufficient friction to transmit acceleration and braking from the rim to the trail and vice versa. It has tread blocks to grip the road and trail, tread voids to shed mud, snow and water, and it can have cap-plies or steel belts under the tread to stabilize the tread and reduce punctures. The plies themselves are made of chords of fibrous material (polyester, fiberglass, nylon, rayon, steel mesh, kevlar, etc.) woven together and coated with rubber. It is the plies in a tire that give the tire shape and strength and prevent it from expanding like a balloon, thus allowing the build-up of load supporting pressure. What are the parts? The major parts of a tire are as follows: Body: The body, also known as the carcass or casing, is the core of the tire. Made up of body plies, it is beneath the tread and inside the sidewalls. Chords: Lengths of fibrous material (polyester, kevlar, nylon, etc.) that lie at the heart of a ply. Ply: A fibrous, fabric layer made from chords woven together and coated with rubber.

Bead: High-strength, rubber-coated, steel cable that clamps the tire to the rim. Tread: A compound of many natural and synthetic rubbers and other components that contacts the road.

Sidewall: The rubber between the tread and the bead, it provides lateral stability for the tire and protects the body plies. Shoulder: The area where the tread and sidewall meet. Inner liner: The innermost rubber layer in a tubeless tire that helps to make it air-tight. Steel Belts: Belts of steel mesh that lie under the tread to provide puncture resistance and keep the tread area flat for maximum road grip. Edge Cover: Optional special circumferential reinforcements above the steel belts found in high-speed tires. Also called belt edge strips. Essentially, a tire is made as follows: - The beads are formed from steel

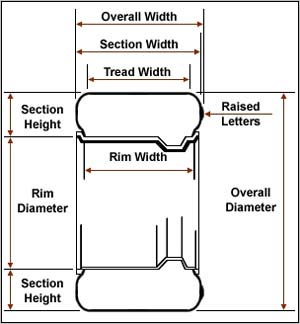

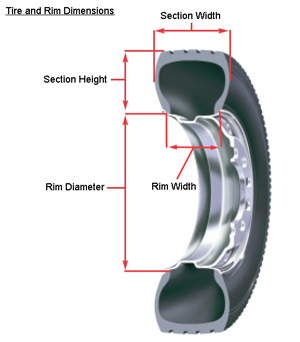

cable Dimensions To have a meaningful discussion about tires, in addition to knowing the names of all these parts, there are some important dimensions of a tire that we must know. These are illustrated and described below:

Overall Width: * Since a tire's section width

and diameter changes depending on the width of the rim on which it is mounted

(the tire gets wider and shorter if mounted on a wide rim, and narrower and taller

if mounted on a narrow rim), each tire is measured on a specific rim width,

called the "design rim". For tires with aspect ratios between 50 and

80, the design rim width is usually 70% of the tire's section width. For tires

with an aspect ratio less than 50, the design rim's width is normally 85% of

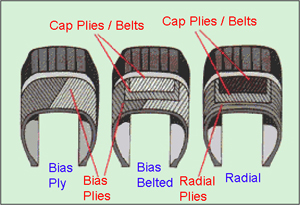

the tire's section width. Aspect Ratio = Section Height divided by Section Width Aspect Ratio is the relationship of a tire's height to width when mounted and inflated on a rim of correct size. Aspect ratios are expressed as a two digit percentage such as 80, 70, 60 etc. This number, as a percentage, means the height of the tire's sidewall (its Section Height) is x% of its width. Aspect ratios are also often referred to as the tire's 'series'. For example, if section height/section width is 0.60 (60%), the tire is a 60 series tire. Why do we care about a tire's Aspect Ratio? Because the height to width relationship determines the shape of the tire on the rim, and, more importantly, determines the performance characteristics of the tire. If the sidewall height of a tire is reduced slightly, the sidewall stiffness is increased greatly. Higher Aspect Ratios deliver greater deflection under load and a softer ride. Lower aspect ratios deliver a wider footprint, quicker response, less slip angle, lower flex rate, less deflection and a harsher ride. Also, typically, a high aspect ratio tire will have a long, narrow footprint, while a low aspect ratio will have a short, wide footprint. At least that's all true in the street-car world. Things are a little different for us because the amount by which we air down our tires overrides the Aspect Ratio in determining the tire's footprint and responsiveness. Construction - Radial, Bias Ply, and Bias Belted There are 3 basic types of tires, named for the 3 main ways of constructing a tire, differentiated by the way the body plies are oriented. They are:

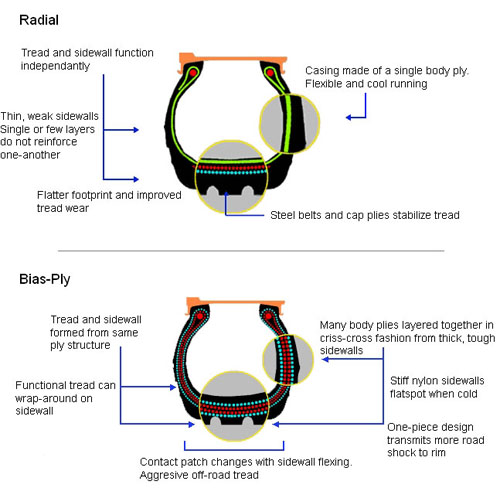

Bias Ply The body plies in a bias ply tire are laid down at an angle (or bias) to the centerline of the tread, and are stacked one upon the other in a multi-layer criss-cross fashion. These criss-crossing layers are generally oriented 32 to 40 degrees from the centerline of the tread. Since the chords that make up the plies are fibers, they are strong in tension but have no strength in compression. This is why the plies are laid down at a bias and on top of one another - to give the tire its strength in both directions - and is also why there are always an even number of body plies in a bias ply tire. The body plies are frequently made of nylon chords but other materials can be used. Nylon is very strong but is also very stiff. These stiff, strong layers must essentially scissor against each other as the tires flexes which builds heat, causing the tire to run hotter than a radial. Over time, heat degrades a tire. That said - this building of heat is really only an issue in sustained road driving at speed. Bias ply tires also do not have cap plies or steel belts under the tread - as a result, when the tire is loaded by the vehicle the chords are stretched and the entire body supports the weight. Since there are no other layers under the tread, the tread tends to be slightly rounded, creating a smaller contact patch (relative to a same-size radial) that reduces road handling. Because of our practice of airing down this reduced contact patch is of no concern off-road. On the other hand, since bias body plies run from bead to bead there is no transition from a circumferential belt to sidewall - the tread and sidewall construction are the same. As a result, tread can be wrapped around and down the sidewalls of a bias ply tire for extra traction and protection - the perfect example of which is the Pitbull Rocker- a tire not offered in radial design.

The overlapping, criss-cross plies of a bias ply tire results in a carcass and sidewall that are thick, stiff, and strong. This very strong sidewall more easily withstands trail hazards and punctures than a radial design (where all the chords run in the same direction, are generally made of weaker, more flexible polyester, and there are fewer plies). This is not only because the multiple plies result in a great thickness (making it harder to penetrate completely), but also because of the alternating angles of the bias ply. If an injury does occur in the sidewall of a bias ply tire it is much less likely to completely rip or tear (called a "zipper") than radial tire. Imagine it like this: take 2 wooden boards and glue/bond them together with the grains running in the same direction. Now strike the top edge with an axe - they will split readily....the zipper! Now, bond the same two boards together again, but this time lay one on top of the other at an angle (a bias) of 30-40 degrees. They will now resist splitting completely when struck with the axe - just like the overlapping body plies in a bias ply tire (when abused offroad - not hit with an axe, of course!) A bias ply tire can be aired down lower than an equivalent radial tire. This is because the heavy-duty sidewalls of a bias ply tire also help support the load more than in a radial. Remember that the plies criss-cross across a bias ply tire. One layer is strong in the weak direction of another. As the tire is compressed and flattened by the load, some of the cords are put under tension where the great tensile strength of nylon results in the sidewall supporting the load in conjunction with the air pressure inside the tire - the result being we need less air pressure in the tire to support the load. Bias ply construction also presents two additional characteristics - neither of which are of any real concern in a hardcore trail rig. Due to their weight and lack of steel belts or cap plies, bias ply tires tend to be less fuel efficient for highway use than radial tires. Also, nylon has a tendency to take a set when statically loaded, especially when cold, resulting in the "square tire" syndrome. Radial There are two main differences in the construction of radial tires compared to bias ply tires that account for their dramatically different on and off-road performance characteristics: the orientation of the body plies and the addition of steel belts and/or cap plies under the tread. In a radial tire the body plies are laid down perpendicular to the center line of the tread - they appear to radiate from the center line - hence the name "radial". There are also usually many fewer body plies than in a bias ply design - up to a maximum of 3 compared to the up to 16 used in a bias ply tire. In fact, a radial tire needs only one body ply, and thus is not only less stiff, but runs much cooler, and weighs less. If more than one body ply is used , successive body plies are layered over the existing ones with all the chords being parallel. In addition, the body plie(s) of a radial tire are generally made of polyester which is softer and not as tough or strong as the nylon common in bias ply tires. Radial tires also use a wide variety of cap plies and/or steel belts under the tread. These belts are placed in successive layers circumferentially around the casing, under the tread. They are independent from the body plies, are made from a variety of materials (including steel, fiberglass, and nylon) that are different from the materials used in the body plies, and so cause a discontinuity where the sidewall and tread meet. Each belt adds an additional layer in the tread area but leaves the sidewall area untouched. This belted radial design, this discontinuity between sidewall and tread, results in the tread being independent from the sidewall - the steel belts provide a stable foundation for the tread allowing the sidewall to be more flexible. In a radial tire sidewall flexing does not alter tread pattern. As the tire flattens out under loads or impact, the sidewall plies just bend, adding very little resistance. The following diagrams illustrate the difference between bias ply and radial tires in terms of the effect of sidewall flexing on tread stability and contact patch.

The combination of the radial pattern, softer polyester material, and use of belts (independent tread and sidewall) gives a radial tire more sidewall flex which allows the tire to absorb road shock and noise thus producing a much smoother ride. The softer polyester chords also resist flat-spotting much better than the stiff nylon chords in a bias ply - especially in the cold. On-road it also results in the load being distributed equally across the contact area as well as better traction with less heat build up resulting in longer life and improved fuel economy. By restricting tread movement during contact with the road, the belt plies improve tread life. In addition steel belts protect the casing under the tread against high-speed impacts and punctures. However, the sidewall is generally weaker on radial tires than on bias tires when it comes to puncture and damage resistance. Part of this is due to fewer body plies and less rubber being used, and part is due to the fact that, in a radial tire, even a small injury can lead to massive tear because the body plies have all their chords running parallel to one another. Also, since the radial sidewall adds very little stiffness (indeed is designed to be much more flexible), as can be seen in the distinctive radial tire "bulge", the load is almost entirely carried by the air and thus radial tires cannot be aired down as low as bias ply tires carrying the same load. In addition, the discontinuity between tread and sidewall in a radial tire is the reason radial tires don't have substantial sidewall tread. Because the radial design depends on thin, flexible sidewalls it defeats the purpose to add significant rubber tread to the sidewall, and doing so would cause a lot of heat buildup from radial sidewall flexing. In any case, even if some form of tread is added to the sidewall of a radial their will still be a break in the transition from tread to sidewall. Other components found in a radial tire but not in a bias ply are bead chaffers and cap plies - usually built into performance tires to enhance cornering and stability at high speeds. Bias Belted Bias belted tires are a hybrid combination that have criss-cross bias body plies like a bias ply tire, combined with cap plies / steel belts like a radial tire. Frequently the belts and body plies are made from different materials. For example, a polyglass tire may have polyester plies and fiberglass belts. Bias belted tires have a wider tread area than the bias ply - providing better traction and stopping power. They also have more flexible sidewalls than the bias ply, resulting in less internal heat buildup during driving and consequently greater tread life. On the surface they may seem like an ideal compromise - a way to combine the benefits of both radial and bias ply design. However, they of course also combine the weaknesses of both designs. I believe this is the reason they have never really caught on and are all but nonexistent in the market place - very few bias belted tires are manufactured today. This is probably due to the fact that both bias ply and radial tires fit their niche, accomplish their goals, so well that the potential consumer of either is not willing to compromise either with a hybrid tire. Those seeking tough, durable off-road tires with maximum sidewall strength and tread will choose bias ply tires - those seeking on-road performance, tread-life, and handling will choose radial tires. Which One to Choose? Virtually all street/car tires sold are radials due to their superior handling, ride quality, and wear. Radial construction allows the tire to better flex and absorb the irregularities of the road surface. The radial design also produces much less friction resulting in cooler running tires and much longer tread life. But bias ply tires refuse to disappear from the market. The overlapping, criss-cross reinforcement design of bias ply tires makes them very durable. Since the sidewall is as strong as the rest of the body, it can withstand lateral loads, twisting, and bending which would cause a radial to split - especially in an aired-down tire. This strength and durability of the bias ply construction is also a benefit in high torque conditions like when a spinning tire suddenly gets traction. Also because of the one-piece tread/sidewall design, much more aggressive and functional tread can be added to the sidewall of a bias ply tire. The following diagram and table summarize the strengths and weaknesses of radial and bias ply construction:

Summary Bias ply tires are the clear choice for serious off-roading because of their sidewall strength, aggressive tread, and ability to be run at low single-digit pressures. For serious, hardcore trail riding, the strength and durability of the bias ply trumps all - after all, when you're wheeling brutal terrain miles from nowhere the best tire is the one that still holds air! Radials are the best choice for on-road driving because of their softer ride, improved handling, and longer tread life. If you drive both on- and off-road you have to decide which is more important - the road manners of the radial or the toughness of the bias ply. Me - I'll compromise road manners for trail performance every time. If you're compromising, whichever you choose, there are a couple of precautions to note: - When running a bias ply tire on the street, strict attention must be paid to tire pressures. The stiff sidewalls can easily disguise an under-inflated tire. Street driving even slightly under-inflated bias ply tires can be hazardous because the scissoring body plies already build a lot of heat - this is exacerbated by under-inflation to the point that the tires can quickly build enough heat to cause ply separation and catastrophic tire failure. - Radials tires, of course, also need correct air pressure on the street. Excessive heat in a radial tire leads to sidewall cracking, zipper blowouts, and the tread separating from the casing (those rings of tread, or "alligators" you see on the side of the highway are most often the result of radial truck tires, especially retreads, suffering this heat-induced tread separation). Off-road, radials will require more air pressure than bias ply tires to avoid excessive sidewall bulge which could otherwise lead to sidewall splitting or the sidewall getting pinched between the rim and a rock. Tire FAQ What’s the best way to replace a single tire or pair of tires on a vehicle?

What is the maximum weight it should take to balance my tire? The industry standard is approx. 2% of the tire weight. What are tires made of? The average steel-belted radial tire is made up of:

How round is round? Generally, a passenger-car tire is considered round if it has less than 0.030" radial or lateral runout. An LT tire is considered round if it has less than 0.060" radial and lateral runout. Does it matter how I mount the tire on the rim? There are two schools of thought

on this. The wider the rim, the greater the

section width. Section width increases about 0.4” for each additional

inch of rim width (and vice versa). A narrower rim pulls the beads closer together, curving the sidewalls. This increased curvature allows the sidewall to flex more readily. It can also help with bead retention at lower air pressures, although using narrow rims is no substitute for beadlocks. Why do race teams use Nitrogen in their tires instead of air? Race cars, aircraft, and other ultra-high

performance machines use Nitrogen in their tires instead of air because, when

heated or cooled, nitrogen has a much more consistent rate of expansion and

contraction than air. What is the difference between an LT and P tire of the same size? LT tires that are load range C or

greater tend to be rougher riding and noisier than their P-Metric counterparts

and more expensive since the LTR size equivalent to the P-Metric has heavier

body ply construction and the tread lugs are generally more aggressive. How should I store unmounted tires?

What about tires on my rig in storage?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Sources: Pit Bull Tire Company |

|