|

Doubler™ Basics

By Bill "BillaVista" Ansell

Photography: Bill Ansell

Copyright 2008 - Bill Ansell

(click any pic to enlarge)

|

|

Concept

Using dual transfer cases in a 4WD vehicle to provide super-low gear reduction has several distinct advantages over other methods of achieving very low gearing (namely using an aftermarket transfer case and/or using very low gears in the differentials.) This method of using two transfer cases is often called a “doubler” because of the doubling of the rigs’ low-range. |

|

The term Doubler™ is a registered trademark of Offroad Design, a Colorado based company who were pioneers in the commercial application of this technology. The advantages of the Doubler™ approach are:

- Budget – when you’re building or modifying a rig, it’s possible to use a stock or common junkyard transfer case to get the rig mobile, and add a Doubler™ later, rather than having to budget for an expensive transfer case from the start. If the transfer case you’re using requires upgrading or rebuilding first, you don’t loose the investment you make in this when you add the Doubler™, as you would if you moved to a completely new transfer case.

- Brute strength – the Doubler™ concept can be applied to the stoutest transfer cases available, such as the NP 203 and NP 205. The result is a bulletproof all-gear, cast-iron drive-train; key parts of which are commonly and cheaply available, as are rebuild parts anywhere in the country.

- Super low gearing – while the lowest low-range available in an aftermarket transfer case is about 5:1, you can easily combine a Doubler™ with aftermarket gear sets in both transfer cases to achieve a low-range reduction of 9:1 or lower.

- Ring & pinion strength – by using the Doubler™ to achieve super-low gearing, you can leave the ratios in your axles' differentials comparatively high. The benefit is a stronger ring & pinion. As ring & pinion gears get lower in ratio their strength diminishes due to the requirement to use a smaller pinion. In addition, using a Doubler™ can make sourcing ring and pinions, especially spares, cheaper and easier since you can use higher ratios that are commonly available in stock vehicles and junkyards.

- Gear options – an aftermarket transfer case with a very low low-range will not increase the number of gearing choices you have over a stock transfer case – only lower all your gear ratios. In contrast (and this is the biggest advantage to the Doubler™ in my opinion), a Doubler™ can literally double the number of available gears you have – making it a great choice for rigs that must tackle a variety of terrain. For example, let’s assume you have the following theoretical drive-train (numbers simplified for clarity): 4-speed manual with 6:1 first gear, transfer case with 3:1 low-range, and 4:1 gears in the axles. Your lowest gear would be 6x3x4 = 72:1 and you’d have a total of 8 gears (4 high-range and 4 low-range). Now, if you swapped in a transfer case with 4:1 low-range and changed to 5:1 differential gears, your lowest ratio dips to 6x4x5 = 120:1, a significant improvement. However, you would still only have 8 total gears, 4 low-range and 4 high-range. On the other hand, if you were to add a 2:1 Doubler™ in front of the original transfer case and make no other changes, your low gear becomes 6x2x3x4 = 144:1. More significantly, you retain your original 8 gears with the Doubler™ in high (1:1) plus you get 8 more gears with the Doubler™ in low (2:1). Admittedly, not all 16 gears will be useable as the ratios may well not be different enough from one another, a fact exacerbated if your transfer case and Doubler™ have the same low-range ratio, nonetheless the point is clear.

The concept is fairly simple: take the gear reduction portion of one transfer case (the low-range box) and mate it to the front of a regular transfer case. The low-range box serves only to reduce the gear ratio, while the regular transfer case provides its own additional low-range gearing along with front and rear drive. Both mated portions are then mounted in the vehicle as a single unit. Since the low-range box will also have a high-range position (almost always 1:1), the Doubler’s™ low-range gearing (often 2:1) can be invoked only when necessary, saving drive-train wear and tear.

Execution

The execution is a little more complex. Commercial systems are available, but it is entirely possible to “homebrew” your own – here’s how:

The basic components required for a Doubler™ are:

- A low-range box donated from an NP203 (203 range box)

- A transmission to which the 203 range box can be mated

- An adapter and shaft to mate the 203 range box to your transfer case

- A transfer case

- Custom shifters

- Custom cross-members

|

|

This pic shows the Wolf’s Doubler.™

Components, from left to right:

- NP203 low-range box

- Custom aluminum adapter

- Jeep Dana 20

- Advance Adapters D20 output shaft.

|

The low-range box

The NP203 is the clear champion as far as being the donor of the low-range box, and for good reason. The all-gear, heavy-duty, cast-iron NP203 has distinct advantages, namely:

- Availability – At some point over the years Chevy, Dodge, and Ford all used the NP203 in full-size trucks, often behind both manual and automatic transmissions. That means finding one that will mate to your tranny of choice is fairly simple.

- Price – in stock form the NP203 is a huge, heavy, chain-driven, full-time transfer case that is not well regarded or very desirable. As such, they are commonly available at very low cost. This is a great boon for the Doubler™ builder, as only the low-range box portion is required, which suffers none of the drawbacks of the rest of the transfer case.

- Size and strength – the 203 range box, when separated from the rest of the case, is a fairly compact 6” in length, has a very strong cast-iron case, and uses large helical reduction gears (Figure 3). It can stand up to big block power without any difficulty.

- Shifting – although the stock NP203 shifting arrangement is a complex contraption that Murphy himself must have designed, once separated, shifting the low-range box alone is simple and easy. In fact – unlike just about every other case I’ve ever shifted, my 203 range box has never failed to shift smoothly and easily. Constructing a shifter is also a very simple affair.

Identifying an NP203

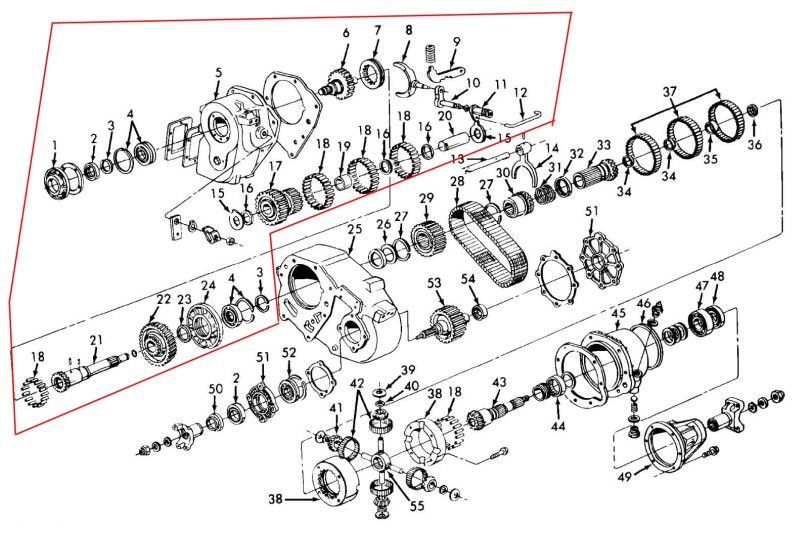

The most distinguishing feature of an NP203 is its massive size – it dwarfs even the NP205. Measuring 22” long, 19” wide, 15” high and weighing in at a humongous 165 lbs it is one big beast. The following diagram illustrates an exploded view of the NP203, with the low-range box components used for a Doubler™ outlined in red.

Other features of the NP203 are:

- 2:1 low-range gear set (1.96:1) and 1:1 high-range.

- Chain-driven, full-time 4WD with differential.

- Stock shifter positions, labeled on the shift knob, are: High, Lo, High Lock, Lo Lock and Neutral.

- Consists of a cast-iron low-range box coupled to a large aluminum chain-drive case that includes the front output. Behind the chain-drive case is the housing for the full-time 4WD differential, and behind that is the rear output.

Like all New Process transfer cases it should have a model ID tag; in this case located on the front of the aluminum chain-drive housing, just above the front output. |

|

Figure 3 – large helical gears inside the 203 range box. |

Details of the NP203 used by each manufacturer are as follows:

Ford

Available behind C6 automatic transmissions, the Ford NP203 has a 31-spline input and Ford 6-bolt circular bolt pattern. It will also mate to manual transmissions such as the NP435 that have a 31-spline male output. The Ford NP203 came as an option in:

- '73-’77.5 F-150/100.

- '77.5-'79 F-150/100 and F-250.

- '78-'79 Full-Size Bronco.

Note that the '73-’77.5 F-250 may come with an NP203 but it will be divorced and not practical to use for a Doubler™.

Chevy

General Motors used the NP203 in some full-size pickup trucks and Blazers from approximately ‘71-‘79, and behind the following transmissions:

SM465 4-Speed manual – 10-spline female input.

TH 350 Auto – 27-spline female input.

TH 400 Auto – 32-spline female input.

The Chevy NP203 bolt pattern is a unique, 7-bolt asymmetrical pattern, as seen in Figure 4. |

|

Figure 4 – Front input of Chevy NP203 showing asymmetrical 7-bolt pattern and 10-spline input indicating SM465 version. |

Dodge

Dodge used the NP203 behind both TF727 autos and NP435 manuals from ‘75 to ‘79. Dodge NP203s have a 23-spline female input and use either a 6-bolt circular bolt pattern (later models) or the Chevy style 7-bolt asymmetrical pattern.

Note that in the case of the Chevy and Dodge 7-bolt asymmetrical pattern NP203, it is possible to re-drill the low-range box case so that it fits the 6-bolt circular pattern.

Transmission

The 203 range box can be mated to the following transmissions using a factory adapter:

Ford – C6 automatic; NP435 4-speed.

Chevy – TH350 and TH400 automatics; SM465 4-speed (Figure 5).

Dodge – TF727 automatic; NP435 4-speed.

With custom work or an aftermarket adapter the 203 range box can also be mated to various other transmissions, including the NV4500 5-speed. Typically this involves replacing or machining the transmission’s output shaft to match the NP203 input, along with re-drilling the 203 range box to match the adapter on the back of the transmission. |

|

Figure 5 – Stock Chevy SM465 to NP203

adapter, showing asymmetrical 7-bolt pattern. |

Transfer case

Once you have the 203 range box mated to your transmission, you need a transfer case to mate to the back. The NP205 is the most popular, chosen for its strength and durability. However, the Dana 300 and Dana 20 also make good choices, especially where size and weight are at a premium; both being compact, all-gear, cast-iron cases. This is particularly true if you already have a D300 or D20 that’s been built up with aftermarket output shafts or low-range gears. The homebrew Doubler™ setup in my rock buggy, The Wolf, uses an NP203 low-range box and a Dana 20 that has been upgraded with an Advance Adapters rear output and Teraflex 3.15:1 gears. It is also possible to mate the 203 range box to an aftermarket transfer case such as the Atlas II.

Adapter and Shaft

The key to a Doubler™ setup, and the heart of the system, is the adapter and shaft that mate the 203 range box to the transfer case. The job of the adapter is to mate the 2 cases together and support the shaft that transfers the power from the 203 to the transfer case.

In the Wolf, the shaft is simply the stock 203 range box output shaft (that would have driven the chain-drive gears in the stock case) that is cut down and re-splined to accept the Dana 20 input gear. Figure 6 shows the modified shaft. It was cut down on a lathe and re-splined with a vertical mill. It wasn’t heat treated after this surgery because we lacked the facilities to do so. In theory this presents a weakness, but in practice, several years of hard use have failed to result in any problems with the part. |

|

Figure 6 – Cut down and re-splined 203 output shaft. |

| The adapter itself is a single piece of 6061-T6 aluminum, 1.5 inches thick, that is machined on the front face to accept the large basket-like 203 output bearing retainer. The rear face is machined to accept the output-shaft bearing and retainer from the transmission originally in front of the Dana 20 transfer case, in this case a Jeep™ T150 3 speed manual transmission. Figures 7 and 8 show the adapter. In addition, the bolt pattern from the rear of the 203 range box is drilled into the front of the adapter, and the bolt pattern from the front of the Dana 20 is drilled into the rear face of the adapter. |

|

Figure 7 – 203 range box (front) side of adapter. Note multi-step profile of machining to accommodate bearing retainer basket. Also note two counterbored holes on bottom circumference of basket recess. These 2 counterbored holes contain bolts that retain the transfer case onto the rear of the adapter, but that thread from the front of the adapter. |

| |

|

Figure 8 – Rear side of adapter, to which the transfer case mounts; machined to accept the T150 3 speed transmission output shaft bearing. Note the large hole that allows gear oil to flow from the 203 range box to the transfer case. This permits filling both cases with 85w gear oil from a single point on top of the 203 range box. |

Putting it all together

As hard as it is for any writer to admit, a picture really is worth a thousand words; and so to save you about half a million of them, the best way to understand how the whole system goes together is to study the following series of pictures that illustrate the disassembly and re-assembly of the Wolf’s Doubler™. |

|

Adapter being removed from 203 range box. Note that the aluminum adapter is sandwiched between the 203 low-range gear and the Dana 20 input gear. |

| |

|

Disassembled components of the Doubler™, from left to right, 203 range box, adapter with shaft, Dana 20. |

| |

|

Adapter attached to transfer case. Note the two recessed bolts (just at the circumference of the large gear) that thread into the transfer case. |

| |

|

203 range box (front) side of adapter. |

| |

|

Transfer case (rear) side of adapter. |

| |

|

Transfer case input gear (main drive gear) being removed from Doubler™ shaft. |

| |

|

203 low-range gear with shaft, bearing, and bearing retainer “basket” removed from aluminum adapter. |

| |

|

Shaft and gears being replaced in front side of adapter. Note locating tab on bearing retainer basket which fits into corresponding slot machined into adapter. |

| |

|

T150 3-speed transmission output bearing and retainer being placed over shaft on rear side of adapter. |

| |

|

Bearing and retainer fit into recess machined into rear side of adapter. |

| |

|

Transfer case input gear being installed on Doubler™ shaft. |

| |

|

Transfer case input gear secured onto custom Doubler™ shaft with locknut using thread locking compound and torqued to 300 ft-lbs. |

| |

|

203 range box, adapter, and transfer case bolted together; ready for installation into the vehicle. |

Conclusion

While certainly not a simple project, building your own Doubler™ is quite achievable for those that have the required machining skills or access to someone who does. The key lies in machining the adapter to accept the 203 range box bearing supports and modifying the 203 shaft to accept the transfer case input gear. Very special thanks go to Rue Armstrong who artfully created the system you see here, many years ago before it was a well-known approach, and pretty much off the top of his head. Unfortunately, because he is such a gifted fabricator, able to work from instinct, there are no detailed plans or measurements available – but I hope the pictures and descriptions given allow you to create your own custom system. Good luck, and whatever you do, keep the nuts tight! |

|

|