|

1 Ton 1350 CV Driveshaft Review

By Bill "BillaVista" Ansell

Photography: Bill Ansell

Copyright 2003 - Bill Ansell

(click any pic to enlarge)

|

|

Introduction

First question. Why did

I choose to get my driveshaft from High Angle Driveline, all the

way in California? Simple Answer - they are the best.

Why are they the best?

1) The product is the

best. Jess understand and caters to the hardcore off-road crowd.

His shaft can be found in more top rock crawling competitors rigs

than any other. He does what other driveshaft shops will not or

can not do. His is the only shop offering a true, re-lubable, 32°

capable double-cardan CV style driveshaft. Period. |

|

Also, High Angle Driveline

driveshafts are built with improved balance and stiffness that result

in less drivetrain vibration and component wear, as well as improved

driver comfort, and reduced noise. The Hytrel™ thermoplastic

booting provides High Angle Driveline driveshafts with enhanced

protection against environmental contaminants, increasing component

life. It has been proven to reduce maintenance and downtime, having

undergone extensive environmental testing in temperatures ranging

from -40°F (-40°C) to 220°F (105°C).

High Angle Driveline

Heavy-Duty Driveshafts offer:

• Larger diameter slip member with longer involute splines.

Long travel shafts available with up to 18" of slip-spline

travel

• Long life - built from the best Spicer components, custom

machined, fully welded, and available in .083, .120, and even .250

wall tubing

• Re lubable slip spline

• Reduced maintenance - Net-formed Spicer Life series U-joints

used throughout

• Custom precision machining and balancing

• Increased torque capacity

• Personal hand crafting and the best customer service in

the business

2) The customer service

is the best. Jess is one

of those few, very rare vendors that truly, truly stands behind

his product. he calls YOU to make sure you are happy and satisfied.

He goes that extra mile, no questions asked. He also freely shares his

knowledge and experience, even when

doing so may help someone in a manner that might cost him a sale

(like helping with junkyard part numbers or dimension - instead

of just trying to sell a joint or yoke) - now That's unselfish dedication

to the hobby/sport and it's fans - you and I. My own story of customer service

experience with Jess is told

below. |

|

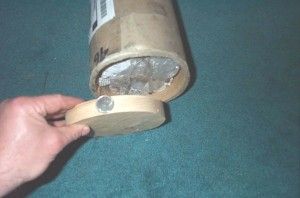

Here's

how my driveshaft arrived. A far cry from the last driveshaft I

ordered from a US "specialty shop" - that one arrived

half unpainted, scratched, and with only a bit of tape holding the

U-joint caps on - no packaging at all. |

| |

|

In contrast - my High

Angle shaft was solidly and carefully packaged. Good thing too - considering

the trip it had. You see - Jess shipped my shaft to me UPS, all the way to Nova Scotia, Canada. For

reasons unknown to this day - Canadian or US customs or UPS brokerage,

I don't know which, refused to let the package cross the border/clear

customs (despite the outrageous brokerage fees UPS charges), and bounced

it back all the way from Montreal to California. Jess immediately phoned me, apologizing profusely (even though it was in

no way his fault). He explained that, when he phoned to straighten

it out, UPS told him the package wouldn't clear without my Social

Insurance number on it. Jess defended my privacy rights and watched out for my security without

me knowing or having to ask, by telling them to pound sand, and that

that wasn't good enough. Eventually, after wasting a lot of his valuable

time, he was able to get them to relent and agree that my phone number

was enough. he wasted no time telling them what he thought of that

- seeing as that was what he had originally had on the package!! Anyway

- in the end, he ate the nearly $90US double shipping charge, and

re-sent my package immediately. It promptly arrived, unscathed! |

| |

|

You may have already

read how I am a HUGE fan of well packaged products - perhaps just

because I've been so disappointed in the past with shoddily packaged

goods. But I think it's more than that. It really shows pride and

care in a product, and it says "I care about how my product

gets to you - not just about your credit card number"

I like that - a lot!

So I love this package - just look at the super sturdy packaging! |

| |

|

Inside the 1350 CV shaft

and patented 32 spline flange (U.S. Patent USD 462,256,S) are carefully

shrink-wrapped. |

| |

|

The package includes a

new mounting nut for the transfer case output flange, and 4 high-strength

12 point socket head cap screws for securing the Driveshafts CV socket

yoke to the custom transfer case output flange. |

| |

|

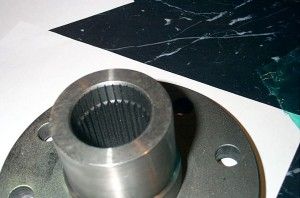

The custom machined, 32

spline transfer case output flange. This flange is available for New

Process (NP) 203 or 205, 32 spline HD fixed yoke conversion kits (e.g.

Advance Adapters) for the NV 231, Advance Adapters, JB conversions,

Tera Mfg., etc) Atlas with 32 spline output, and Dana 20 and Dana

300 with Advance Adapters 32 spline output conversions. |

| |

|

The flange is also available

for 26 spline output shafts, such as in the Dana 20, Dana 300, NP

207, 231 & 242, and 26 spline Atlas. However - 26 spline outputs

are not recommended as being a good match with a 1350 1 ton shaft,

as the shaft is now much stronger than the transfer case output. |

| |

|

Close up of the beautiful

machine work. Check out the splines. Be aware that switching to the

High Angle Driveline flange will shorten the length your driveshaft

needs to be by 1/4" |

| |

|

The transfer case output

flange and CV socket yoke flange (see how useful that new vocabulary

is 0 you know exactly what I mean, don't you!) come marked with a

flash of bright paint so that they can be installed with proper original

phasing, as manufactured and balanced at High Angle. |

| |

|

Here's a peek at the

heart of the system. the ball and socket assembly of the CV centering

yoke are DEFINATELY NOT stock. They are specially modified and machined

to be stronger than stock Spicer components, capable of much higher

angles, and still lubable (see grease fitting in pic).

High Angle is the ONLY

driveshaft shop building 1 ton 1350 CV shafts like this! |

| |

|

Here's a shot of the whole

package together - shaft, flange, and mounting hardware. The 1350

CV driveshaft as pictured is normally available in lengths from 135/8"

to 65-70". |

| |

|

A close-up of the CV head

assembly, showing off the CV joints high angle capability. Capable

of running at 32°. |

| |

|

The shaft is fitted with

3 of Spicer's latest and greatest Spicer Life Series universal joint,

in 1350 series. |

| |

|

An interesting feature.

Jess welds up the welch hole. The reason is, if it were left open,

should the driveshaft ever be submerged in water / mud, and extend

while so submerged, it would act like a big ol' turkey baster and

just siphon up a big gulp of mud / water This would almost certainly

then sit inside the shaft and the cause unnecessary wear and corrosion

to the slip member splines. For extreme off-road use, it is better

to leave it closed. |

| |

|

When he builds you a 1350

1-Ton CV driveshaft - Jess starts with the best Spicer OEM components...but

that is only the beginning. I can't tell you exactly what magic he

works, as that is a trade secret. But I can assure you, the CV joint

is significantly worked over, resulting in greater strength and much

greater operating angle capability than any stock Spicer unit. |

| |

|

Just look at the attention

to detail and fine craftsmanship. It's a beauty, no doubt. Standard

travel in the slip member is 5" for a rear shaft like this, set

at 2" compression and 3" extension. Of course, many other

configurations are available. For example, standard long travel shafts

offer 12-14" travel in the slip member, usually set up for 3-4"

compression and 8-9" extension. |

| |

|

Here's a shot of the pinion

end. The shaft comes with all the U-joints installed and lubed, ready

for use. You just need to install it and go. |

| |

|

Here's another shot of

the complete package - 1 Ton 1350 CV Driveshaft, custom machined,

patented (U.S. Patent USD 462,256,S) 32 spline output flange, and

all the necessary installation hardware. The standard tube size is

3" .083" wall tubing, which is light, stiff, balances well,

and has a strength at least equivalent to the 1350 CV joint. For those

who require or desire it, High Angle Driveline can make your shaft

with either .120" wall tubing or even .250" The latter is

only for very special requirements, as it is hard to balance, and

spinning a shaft of that much weight is hard on the other drivetrain

components. |

| |

|

Here's a pic of the junk

I was replacing. Due to my suspension, drivetrain length (with dual

transfer cases) and wheelbase, the slope between my transfer case

and rear axle pinion is pretty high. The yellow arrow shows the butch

homebrew redneck booty fab method I had employed to prevent the shaft

from binding. Clearly, I was well beyond the design limitations of

these components. |

| |

|

You can clearly see where

I had ground the yoke for clearance. This does nothing for strength,

reliability, or to combat vibration and noise! |

| |

|

Here's one last pic of

the rusty, poorly welded, unbalanced, out of phase, banana shaped

shaft that had to go! |

| |

|

Old vs. New. What a difference

!! |

| |

|

Just look at the beefier

yokes, and much bigger and better U-joints. Notice the increased dimensions

of the new Spicer Life bearing caps |

| |

|

More beef, better machining,

perfectly balanced, bugger joints...what's not to love! |

| |

|

Installation is straightforward.

Refer to my article, "The Driveshaft Bible", for further guidance if required.

First I removed the transfer case output yoke and retaining nut. Then

I coated the splines of the new flange with RTV to ward off any leaks,

and installed the flange onto the transfer case output shaft. |

| |

|

Coat the face of the nut

with RTV, and apply a little Loctite thread retention compound to

the internal threads of the nut. |

| |

|

Install the nut and torque

to at least 150 ft. lbs. |

| |

|

Then simply mate the driveshaft's

CV joint yoke flange to the output flange, and secure with the 4 supplied

12 point bolts. The bolts come with retaining compound already impregnated

in them, but Jess recommends using Loctite anyway, and tightening

them to 80-90 ft. lbs. |

| |

|

The axle end just installs

as normal. Remember to be careful not to over-torque the bearing cap

retention hardware, as this distorts the cap and increases premature

joint wear. |

| |

|

When you're tightening

the fasteners, take your time, do them in a gradual, cross pattern,

and you will have no difficulties. |

| |

|

Here it is, all installed

and ready to go. At rest, my shaft operates at an angle of about 27°,

which is pretty high. See if the High Angle Driveline 1350 CV shaft

is up to the task, below in the testing section. |

| |

|

Installed pic #2 |

| |

|

Installed pic #3 |

Testing

Of course, shortly after

installing the shaft, I had to take it out and absolutely romp on

it. The funny thing was, the thing that amazed me most, was not

what I was expecting. I was expecting, because of his skill and

reputation, that the shaft would easily handle my abuse, and I wouldn't

be disappointed.

What I wasn't expecting,

was how amazingly much more pleasant and enjoyable it was to drive

my buggy with a quality, balanced, driveshaft operating within it's

angular capabilities. You see, my buggy is, obviously, a rugged,

trail only machine. It's not tight like a sports car - it's rough,

tough, harsh, and noisy - the way it should be - or so I thought.

WOW - getting rid of the

old home-brew, unbalanced, "banana shaft" made a huge,

dramatic increase in how smooth and pleasant it was to drive. Sure,

you still get bugs in the teeth, can't hear yourself think over

the 350, and will never get confused and think you're in a Mercedes

- BUT - it is much smoother to operate now - both at trail speed,

and buzzing down the fire roads at 40mph. I'm truly amazed by this

- and very pleasantly supervised. Cool - thanks Jess!

For testing I wheeled

hard enough in this terrain... |

|

|

| |

|

|

| |

|

|

| |

|

To do this (rip track

bar bracket of 3/8" steel like wet tissue paper) |

| |

|

Causing this (total loss

of steering) |

And my new High Angle

Driveline shaft didn't flinch - not one bit!

So it's not only silky

smooth, but brutally strong too.

And take a look at this

series of shots below. Here I'm in 110:1 and with some pretty serious

rear suspension droop. I powered my way through, with no binding,

no breaking, no noise or carnage at all...and that's with my shaft

at 27° AT REST. |

|

|

| |

|

|

This shaft really is

all it is cracked up to be, and then some.

Get One !!! |

|