|

Teraflex T-Locker

By Bill "BillaVista" Ansell

Photography: Bill Ansell

Technical Drawings: Lonny Handwork

Copyright 2005 - Bill Ansell

(click any pic to enlarge)

|

|

Introduction

I had long wanted a selectable locker for the front of my rig. While my

old welded-up spool provided all the traction I ever wanted, the handling

it induced was terrible. The overwhelming tendency for the front wheels

to plough straight ahead while turned, seriously compromised manoeuvrability.

It was especially annoying in tight, technical rock crawling where precision

is key and a few inches can mean making or losing the line. Adding full

hydraulic steering did nothing to help – sure, it reduced the steering

effort a lot, but it can’t make the wheels track a turn the way

an open differential can. I tried various other “solutions”

to the problem: I added cutting brakes and I tried using locking hubs

instead of drive flanges but nothing stopped the front end from ploughing.

And so I knew that if it was the ultimate in both traction and turning

I wanted, a selectable locker I must have. But which one? |

|

There are several choices

on the market, differentiated principally by the way in which the locker is

activated. I immediately dismissed cable and electrically-activated lockers,

as it is difficult for either of these methods to develop sufficient force for

the sure, reliable shifting I wanted. Additionally, the locker’s location

means constant submersion in water, mud, and goo – making it a not-so-great

location for electrical servos. Cable activation would require finicky setup,

a large lever for any real power, and likely constant adjustment and maintenance

of the cable. This leaves pneumatically or hydraulically activated lockers,

but which of these to choose? I’m a big fan of hydraulic power, but it

requires specialized pumps and plumbing, and operates at very high pressure.

Not only that, but Mercedes Benz make the only manually selectable hydraulic

lockers I’m aware of - and only for their own products like the Gelandewagen.

So that leaves pneumatic, or air-operated, activation. Fortunately, pneumatics

is an excellent solution. The beauty of pneumatics is that the plumbing is simple

and cheap, it operates at low pressures (under 100 psi as opposed to 1000+ in

hydraulics), and there are virtually limitless options for supplying the air

- from small electrical compressors to engine-driven on-board air systems to

portable CO2 tanks. Not only that, but most of us will already have some sort

of air supply system incorporated into our rigs. A short time ago, when I heard

that Tibus Offroad (of Unimog axle fame) were designing a new type of pneumatic

locker, I jumped at the chance to install one in my Dana 60, test and review

it. Here’s what I found:

The

T-locker

Figure 1 – T-locker

exploded view |

Figure 2 – Carrier bearing reliefs |

The new T-locker is a pneumatically shifted, manually controlled, selectable

locking differential that gives the operator a choice of fully-locked operation

(essentially operating as a spool) or fully-open operation (operating as

a standard open differential).

The T-locker was designed from the ground up by German

engineer Wolfgang Tibus to be the strongest, most reliable selectable

locker available. The engineering, machining, and fit & finish of

the T-locker are absolutely first rate – and this is immediately

apparent the second you hold one in your hands. Weighing in at over 35

pounds it’s a serious brute of a machine. Not only that, but there

are also several small touches that demonstrate the level of thought and

attention to detail that went into its construction. For example, there

are very generous reliefs machined into the carrier bearing seats –

sure to be appreciated by anyone who’s had to use a twin-leg puller

to remove carrier bearings (Figure 2). |

| |

Figure 3 – Shift collar |

The

way that it works is deceptively simple. Figure 1 illustrates an exploded

view of the locker. Inside the case there are four spider gears, two side

gears, and two cross-pins. The locking ability comes from the fact that

one of the side gears is machined to accept eight hardened-steel locking

pins.

These pins slide in

grooves in the case to engage or disengage the side gear. The position

of the pins is controlled by a sliding shift collar that sits just below

the carrier bearing journal on the non ring-gear side of the case (Figure

3). |

| |

Figure 4 – Shift fork |

The position

of the shift collar is in turn controlled by a shift fork that is built

into the diff cover (Figure 4). When the shift fork is shifted to the “lock”

position, the shift collar slides towards the centre of the case, the pins

engage the side gear, the locker is “locked”, and the axle shafts

are 100% mechanically locked together giving maximum traction. When the

shift fork is shifted to “unlock”, the collar slides away from

the centre of the diff , the pins retract from the side gear, the side gear

is allowed to turn freely, and the T-locker now behaves as an open differential.

The shift fork itself is shifted by a small pneumatic cylinder (very much

like a small hydraulic cylinder) that is mounted on the diff cover (Figure

6). |

| |

Figure 5 – Complete pneumatic system |

There are

two ports on the pneumatic cylinder, one for lock and one for unlock. Applying

air pressure to one or the other shifts the fork in the desired direction,

meaning the locker is powered in both directions. As such it doesn’t

rely solely on a return spring to unlock, resulting in much more positive

shifting than would otherwise be the case.

There is also a return spring, as can be seen in Figure

4. The purpose of the return spring is to return the shift fork, and therefore

the locker, to the desired state, should there be a complete loss of system

pressure. I say “desired state” because of one of the great

advantages of the T-locker’s design – the user can choose

whether the default, pressure-loss position is “locked” or

“unlocked”. The factory setting is “unlocked”,

and this should never be altered for a street driven rig (imagine tooling

along at 50mph with the locker open and experiencing a pressure loss –

the return spring would take over and shift the locker to lock with disastrous

consequences!) However, in a dedicated trail rig, one can simply install

the spring on the other side of the shift fork, causing the pressure-loss

position to be “locked” – which may be an advantage

where maximum traction is a must. As far as I know – no other locker

offers this choice. |

The

Pneumatic System |

Figure 6 – T-locker switch and cylinder |

That said,

a loss of air pressure is unlikely, and even if it happens, it will be quick

and simple to repair – even on the trail. That’s because the

real beauty of the T-locker lies in the simple, rugged design of the pneumatics.

There are only three components involved: the pneumatic cylinder (built

into the diff cover), the switch (mounted wherever the operator desires),

and a supply of air. Figure 5 shows the complete pneumatic system, from

supply tank to cylinder.

The entire air system lies outside the diff cover. This

means that there are no seals on rotating parts to wear or leak, no drilling

into housings or bearing caps required, no gear oil will ever blow back

up the lines, and the system can be installed, troubleshot, and repaired,

even in the field, without ever having to remove the diff cover.

Figure 6 illustrates, from left to right: quick-release

air supply with shut-off valve, locker activation switch, and pneumatic

cylinder with air-lines attached. |

The key to the system is

the very clever switch (centre, Figure 6). The switch is actually a mechanically

operated, two-position, monostable, pneumatic solenoid valve designed and built

by the German company, Joyner Pneumatic (as is the cylinder). What this really

means is that it is ingenious! First, there is no electrical wiring involved

– the switch is mechanically operated (the user flips a toggle) and pneumatically

actuated (only a supply of air is required for operation). Second, there are

only three simple air lines – one from the air source to the switch, one

from the switch to the “lock“ port on the cylinder, and one from

the switch to the “unlock” port on the cylinder.

There are five ports on

the switch, as follows:

1 – Air supply

2 – Lock

3 – Lock-line vent

4 – Unlock

5 – Unlock-line vent

To port 1 you connect an

air supply capable of delivering anywhere from 20-150 psi. Port 2 is connected

to the lock port on the cylinder (the outer port), and port 4 is connected to

the unlock port on the cylinder (the inner port, closest to the diff). Ports

3 and 5 are vents and are left unconnected. |

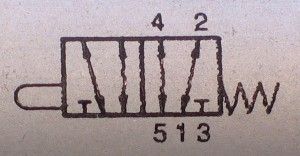

Figure 7 – Pneumatic switch solenoid diagram |

Figure

7 illustrates the solenoid schematic diagram. The diagram shows us that

the solenoid is a two-position, push-button activated, spring-loaded switch

(similar to a spring-loaded on/off switch). There are two positions for

the switch, each represented by a rectangular box in the schematic. The

arrows in the boxes show the connections between the numbered ports, depending

on which position the switch is in. The box on the right, closest to the

spring, shows the connections in the normal (spring relaxed) position,

the box on the left shows the connections with the spring compressed.

With the switch in “normal” port 1 is connected to port 2,

supplying air pressure to the lock side of the cylinder; port 4 is connected

to port 5, venting the unlock side and port 3 is internally blocked off

(represented by the T). When the operator flips the toggle switch a plunger

presses on the activation button, the spring is compressed and the connections

become those shown in the box on the left: port 2 is vented to port 3

(releasing the lock side), port 1 is connected to port 4 (pressurizing

the unlock side of the cylinder), and port 5 is blocked off. In simple

terms, flipping the toggle switch one way pressurizes the lock line and

vents the unlock line, flipping it the other way does the reverse. |

It takes very little volume

to power the cylinder and activate the locker, and it works with pressure ranging

from 20 to 150 psi. Below 20 psi the shifts become a little weak and slow, and

greater than 150 psi puts unnecessary stress on the air-lines and cylinder/switch

seals. Note that the lock and unlock circuits are completely isolated by having

their own vents. This means that a loss of pressure on one side will not affect

the other – in other words, if you rip the unlock air-line, the locker

will remain locked, and vice versa.

In fact, because of this

design, if you install a shut-off valve in the air-supply-to-switch line, it

is possible to pressurize the desired line (lock or unlock), close the valve

in the supply line, and then actually disconnect and remove the air supply completely

and the locker will remain in the desired position. Taking this to the extreme,

you could actually fit your supply line with a Schrader valve and operate the

locker with a small hand-operated bicycle pump! It’s certainly not the

recommended method – but it’s nice to know it could be done if required. |

Figure 8 – Pressure and leak testing |

During testing I was

able to get the locker to shift all the way down to 10 psi. I also disconnected

the air supply and found that the locker requires such a small volume

of air for activation that I could lock and unlock it three times with

just the volume of air in the lines. To test the air fittings I pressurized

the lock line, disconnected the air supply and monitored for leaks (Figure

8). Eleven hours later the line still held pressure, the fork remained

firmly locked, and I got tired of watching it! |

Plumbing |

Figure 9 – T-locker air-line fitting |

Possibly

the trickest parts of the kit are the air-line fittings (Figure 9). There

are two different size fittings, a large one for the cylinder ports and

a smaller one for the switch ports. The larger has British Standard Pipe

Parallel (BSPP) 1/8” x 28 TPI threads (also called ‘G-1/8”

Pipe’, and very common in pneumatics.) The smaller fitting has M5x0.8

mm threads. Both are designed to use either 6x4mm metric or ¼”

SAE air line, and both consist of only two parts. The main body threads

into the port, the small cap slips over the air line, the air line is pushed

onto the nipple on the main body, and the cap is then tightened onto the

main body. There is no separate ferrule to lose or risk deforming when the

fitting is tightened. When the cap is tightened onto the main body, it creates

a sort of “self-flaring” effect on the air-line, resulting in

a leak-free connection. After initial installation the line can even be

removed and then re-attached, unlike a normal compression fitting that requires

replacement of the ferrule.

The only thing not included in the kit is the air-line

itself. You will need to acquire about 20-30 feet of ¼” SAE

J844 Type A or B nylon tubing designed for use in tractor-trailer and

other mobile air brake, instrumentation, and air accessory systems. |

It

should have a temperature range of about -40°F to +200°F and a

working pressure of at least 150 PSI. It is commonly just called “quarter-inch

air brake line”. The beauty is, though it is fairly rugged, if it

should break it is dirt cheap (probably less than 25 cents a foot), available

almost anywhere (you can get it at any tractor-trailer parts house and

many other farm or equipment dealers), and it requires only a sharp knife

to cut to length and a small wrench or strong fingers to install. |

Air

Source |

Figure 10 – Air supply tank |

As mentioned,

virtually any air source will power the T-locker, from bicycle pump to CO2

tank. The best setup is to have some sort of small storage tank, which can

be filled as required from whatever air source you have. I scrounged around

the local surplus store and found a small 2-gallon tank that was originally

connected to a small portable compressor (Figure 10). For some reason I

decided to make it resemble a small nuclear reactor! In fact, each component

has a function. In the background you can see the fill port with quick-disconnect

and manual valve. This allows me to fill my tank from virtually any source

– my engine-mounted OBA compressor, my CO2 tank, or a cheap plug-in

electric compressor. I can even fill the tank directly from my shop compressor

and it will hold enough air for a full days locking and unlocking. On the

outlet side, from left to right, I have the tank pressure gauge, shutoff

valve, filter, regulator with gauge, and a universal air-tool quick-connect

fitting that connects to the supply line running to the T-locker switch.

It’s important to supply the cylinder with clean, dry air and I have

found that 80 psi is about optimum. |

Protecting

the Cylinder |

Figure 11 – Quarter-inch steel cylinder guard |

The only

possible drawback to the externally-shifted design of the T-locker is that

the pneumatic cylinder must be protected – but this is easily done.

To begin with, the cylinder is very compact and securely mounted to the

diff cover (Figure 6). The T-locker also comes with a stout, compact, quarter-inch

steel guard that fits closely over the cylinder, keeping it well protected

without resulting in any overhang or loss of clearance (Figures 11 and 12).

The cylinder-guard bolts to the housing with four 3/8” socket-head

cap screws and to the massive 5/16” cast steel diff cover with two

additional hex-head bolts. |

| |

Figure 12 – Installed T-locker with cylinder guard and air-lines in place |

Even for

those of us, like me, who prefer to “drive by brail” in the

rocks, there should be no concerns with damaging the cylinder. If, however,

the worst should happen, replacement parts are available from Teraflex. |

Installation Essentially,

installation involves assembling the air cylinder to the diff cover, installing

the locker and setting-up the gears, adjusting the shift fork position, bolting

on the diff cover, installing the air lines, and installing the cylinder guard.

The installation instructions provided with the T-locker are actually pretty

good so I’ll just mention the following tips and info I learned along

the way.

Installing the locker in

the housing is the same as installing any carrier, the only exception being

that prior to installing the carrier bearings you must first remove the zip-tie

that holds the shift collar and locking-pins in place during shipment. Once

you have removed it, be careful not to hold the locker in such a way that the

set-up bearing can slide off, allowing the shift collar and locking-pins to

fall out and scatter all over the floor. (Ask me how I figured this out!) Once

the locker is installed and the gears set-up, the only tricky part of the installation

is adjusting the shift fork position so that its throw is both sufficient and

in the right location to completely lock and unlock the locker when the cylinder

is actuated.

I used the following method

to accomplish this: |

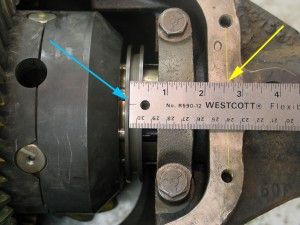

Figure 13 – measuring “lock position” of shift collar |

1. Referring

to Figure 13: Slide the locking collar all the way towards the centre of

the diff, and ensure the locker is fully locked. Scribe a line between the

centres of the two cover-bolt holes on the housing (yellow arrow). Measure

the distance from the inside of the inner lip on the shift collar (blue

arrow) to the line you just scribed – this is the “lock position”

of the shift fork. |

| |

Figure 14 – measuring “lock position” of shift fork |

2. Referring to Figure

14: Scribe a vertical line between the centres of the corresponding bolt

holes on the diff cover. Move the shift fork to the centre, locked position

and holding it in place, measure the distance from the outside edge of the

shift fork to the scribed line. This measurement should be the same as that

obtained in step 1. If it is not, adjust the position of the shift fork

on the cylinder rod by screwing the shift shaft (yellow arrow) and jam nut

in or out, until the measurements are equal.

3. Move the shift fork from locked to unlocked and using the scribe line

on the diff cover as a reference, measure the total throw of the shift fork

from the locked to unlocked positions; the “fork throw”.

4. Returning to the axle housing, and measuring from the scribed line, slide

the shift collar away from the centre a distance equal to the “fork

throw” measured in step 3, making sure that the locker completely

unlocks.

5. With the locker unlocked and measuring from the scribe line again, make

a note of the shift collar’s “unlocked position”. |

6. Double-check the shift fork position as follows: On the diff cover, allow

the spring to return the shift fork to the unlocked position, then measure

from the shift fork to the scribed line as in step 2, confirming the shift

fork’s unlocked position is the same as that for the shift collar.

7. Repeat steps 1-6 until the measurements for the lock and unlock position

of the shift collar are equal to the measurements for the lock and unlock

position of the shift fork. |

When plumbing the system,

the following tips will help:

• Tighten the air-line

fittings into the switch or the cylinder before attaching the air line to the

fitting.

• The switch fittings take an 8mm wrench and the cylinder fittings a 12mm

wrench.

• Cut your air-lines to length using a sharp utility knife, and make sure

the ends are square and burr-free.

• Do not over-tighten the fittings or the air-line nuts onto the fittings

or you risk damaging them. You should be able to attach the air-lines to the

fittings by screwing the nuts down finger-tight. Since I was working in an unheated

shop at about –20°C I found that I needed to use a wrench. Tightening

both the fittings and air-line nuts using one finger on the wrench positioned

about one inch from the nut worked well.

• It’s a good idea to protect the air-lines, at least in vulnerable

spots, with some sort of protective loom. Quarter-inch ID rubber hose makes

a great protective sleeve for where the lines might rub or where they pass through

a bulkhead.

• It’s possible to upgrade the air-lines to a braided stainless-steel

or the like, but I wouldn’t recommend it. Well routed and secured, the

nylon lines should be more than adequate. Also, if one does snag, being the

weakest link, it will be the part to fail – which is OK since it’s

so cheap and easy to fix (it’s very easy to carry a coil of spare line

and a couple of push-to-connect fittings to make a repair). On the other hand,

it would truly suck to have a strong steel line snag and break a fitting, or

worse, strip the internal threads out of the cylinder or switch.

For

Improvement

Nothing’s ever really

perfect, there are always things that can be better, and I’m committed

to always pointing out what I think needs improvement – both as information

for you, the reader and potential customer, and also for the company concerned,

should they wish to act on any of my suggestions. With that said, the T-locker

made this part of my job pretty difficult – there really isn’t a

whole lot that can be improved as far as I can tell, so I’m really digging

here:

• The mounting holes

on the diff cover are drilled slightly oversize, presumably to facilitate installing

the diff cover, getting the bolts all lined up, and getting the shift fork engaged

in the locking collar all at one time. Fair enough - but this necessitates the

use of washers under the heads of the supplied cover bolts. Sadly, the supplied

washers are cheap junk, far too soft for the job. When you tighten the bolts

anywhere near the Dana recommended 40 ft lbs the washers squish and splay out,

becoming useless and endangering proper cover-to-housing clamping load. Throw

them out and use some decent hardened washers, such as SAE Grade 8.

• Quarter-inch air-brake line may be cheap and easy to source, but it

would have been nice to find a 30 foot coil included in the box – purple

would be cool!

• Similarly, it would have been a very nice touch to throw in at least

one spare fitting of each size – just for those of us who like to lose

important little pieces (don’t ask!)

• The supplied instructions were a little “thin” in the plumbing

section, stating merely: “Run 2 hoses to the axle.” That said –

since you’re reading this article I imagine you won’t have any problems. |

|

|

Conclusion

The T-locker is a full-case,

manually operated, pneumatically powered selectable locker with power-lock and

power-unlock ability. It requires only a simple air-system to operate, has isolated

lock and unlock circuits, and needs little pressure and only a tiny volume of

air to work. The entire pneumatic system is contained outside the differential

for strength and reliability and the required air-lines are cheap, readily available

and easy to repair. For trail-only rigs, the locker has the ability to be switched

between “default-locked” and “default-unlocked”. It

comes complete with a rugged cylinder guard and it is very impressive in its

design and quality. Air-line is not included and you have to buy your own decent

quality cover-bolt washers.

So far I have dismantled,

inspected, measured, photographed, rebuilt, tested, installed, plumbed, and

operated my Dana 60 T-locker and I am very, very impressed with it. At first

I was sceptical about the cylinder outside the diff and hesitant about the pneumatic

shifting. However, now that I have first-hand experience with the locker my

concerns are completely put to rest. What remains is for me to take the locker

out for some brutal real-word trail testing, and that’s exactly what I

plan. Stay tuned for a full future update on this highly impressive product’s

trail performance. |

|

|

Sources: TERAFLEX

Tera Manufacturing, Inc.

5251 South Commerce Drive

Murray, Utah 84107

Ph: 801 288 2585

www.teraflex.biz

Tibus

Offroad

Roffhausener Landstr.25

26419 Schortens

Germany

Ph: +49 (0)4421 70691

http://www.killeraxles.com |

|