|

The LS Primer - Part 2

By Bill "BillaVista" Ansell |

IntroductionPart 2 of the BillaVista LS Primer article continues our look at the latest GM small-block V8 engines - the Gen III and Gen IV motors. We pick up where we left off with Part 1, starting with a look at the so-called "truck" engines. |

Turn Key Engine Supply 510 LS2 - photo: Lonny Handwork |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The Gen III/IV Truck & SUV MotorsGM’s use of V8 motors in cars has been fairly limited since the Gen III debuted. Consumer wants have tended to smaller, more fuel-efficient everyday cars, so the big V8’s are restricted to use in just the top few performance models - like the Corvette, GTO, Camaro, and Firebird. There have only been a limited number of these types of models produced in the last decade or so, and consequently, only a few variants of the “car” V8’s – the LS motors. As a result, it’s quite easy to detail all the LS motors individually by their RPO’s, as we have done above. Trucks are quite a different story. GM trucks and SUV’s have been using various displacement Gen III and IV V8 engines since 1998. In the last decade or so, 4.8L, 5.3L, 6.0L, and 6.2L models have been used in everything from luxury SUV’s to big trucks. Various block and head combinations have been used to – from the earliest Gen III 6.0L Vortec LQ4 that used an iron block and iron heads, to the common iron block / aluminum head combination in the LQ4 and LQ9, to the latest Gen IV 6.2L Vortec truck motors that have aluminum blocks and the same high-performance aluminum heads as the Corvette LS3. Add to this the many other variables, including Flex Fuel models, AFM/DOD, VVT, ETC, etc. and the result is a dizzying array of possible RPO’s used to designate different truck motors. In fact, between 1997 and 2008, over 30 different RPO’s have been used for Gen III & IV truck motors. As a result, it is not practical, nor particularly useful for our purposes, to examine each of these engines by RPO listing. In some cases, the only difference between two different RPO truck motors is the flex-fuel designation. Instead, the plan for this section is to cover the biggest, most common, and most popular truck motors by RPO, and cover the rest as a group by displacement. To keep things even more concise (and therefore readable / useful) I will not be covering the following Gen III/IV engines:

The good news is this. The entire family of Gen III and IV motors were conceived, designed, engineered, and produced from the start to share common architecture so that they could be used in a variety of displacements and applications with minimum investment in design, tooling, and production. This is great news for builders, hot-rodders, and swappers. It means that, essentially, the main basic features of a 5.3L SUV engine are the same as for a 6.0L iron/aluminum truck engine which are the same as for a 6.2L all-aluminum LS motor. Obviously, there are specific differences between the motors in everything from cams & valves to cranks to pistons. And within any group of engines, whether grouped by year or application or material there are the usual year-to-year changes in things like sensor locations, etc. But, all the third and fourth generation motors share a great deal in common – which means tech and parts swapping and build-up techniques are most often completely compatible between the motors. For example, a 6.0L is generally a 6.0L, whether it be an iron block LQ4 truck motor or an all-aluminum Corvette LS2. This means you can put LS2 heads, intake, oil pan, and even cam and valvetrain in an iron 6.0L. This is not only great news for builder and tinkerers, but also for me as a writer (and you as a reader!) as it means we don’t have to go through every single truck motor by individual RPO. Gen III Truck Motors at a GlanceGen III – 1999-2007

*Applications listed here are intended as a rough guide only. Gen IV Truck Motors at a GlanceGen IV – 2005 – 2009+

* Applications listed here are intended as a rough guide only. Gen III Truck Motors in DetailI will not be going into as much detail on the truck motors as I have with the car motors. There are a few very good reasons for this. First, there are far more Gen III/IV V8 truck motors, used in far more truck/SUV platforms, over a much wider span of years than there are car motors. This makes covering every variant, and every change year-by-year, impractical and way beyond the scope of this article. Second, as we have discussed, the Gen III/IV motors were designed from the start to be used in many different platforms and therefore share much common architecture and many design details between them. There are differences, of course, but rather than outline every one, RPO by RPO, year by year, I have summarized the major differences between car and truck engines in the next section. For easy reference I also provide a table grouping Gen III / IV motors together by displacement so that you can easily identify which car and truck motors are close cousins. Before I do that though, let’s take a quick look at a few of the biggest, most powerful, most desirable of the “truck” motors. Since many of these motors have had long runs and been used in many, many applications I have generally taken the specs and details from the latest / most powerful editions of each RPO. LQ4Generation: III

Notable Features: A steel camshaft provides excellent durability. Steel roller rockers add stiffness, allowing greater engine speed with less vibration than previous truck motors. Hydraulic roller lifters reduce friction and internal loss of power for fuel economy and wear resistance. ELECTRONIC THROTTLE CONTROL (ETC) In 2003, the LQ4 was modified for installation in the new Express and Savana vans. The LQ4 for vans is essentially the same as the variant installed in Chevrolet Silverado and GMC Sierra pickups, with two packaging adjustments: The oil pan on the LQ4 was modified with a slight scallop in its sump to allow clearance over the van’s front suspension. In developing the new pan, engineers learned that the design further stiffened engine structure and reduced the oil pan’s natural tendency to magnify mechanical noise generated by the engine. With that information, and the desire to make common as many parts as possible, GM extended use of the Express/Savana oil pan to all Gen III Vortec V8 applications. For the vans, the oil-fill tube and dipstick are extended. LQ9Generation: III

Notable Features: Applications: All 345 hp / 380 ft-lbs 2002-2004 Cadillac Escalade Gen IV Truck Motors in DetailL92Generation: IV

Notable Features: The L92 is basically the truck version of the LS3, although it preceded the LS3 by a year. More accurately, the LS3 was developed from the L92, particularly the amazing high-flow cylinder heads that first appeared on the L92. The L92 cylinder heads are based on those developed for the high-performance LS2 and LS6 car V8s. However the L92 heads improve considerably on both the LS6 and LS2 heads. The L92 heads have offset rockers, like those in the LS7. They also have larger valves than other Vortec V8 heads and increase airflow in and out of the engine for higher horsepower. A special high-lift cam, with 12.7 mm. maximum lift (compared to 11.6 mm in most other Vortec V8s) takes full advantage of the improved flow characteristics. In conjunction with unique pistons, the high-flow heads give the L92 a 10.5:1 compression ratio. They are the single biggest contributor to the L92’s increased horsepower compared to other Vortec V8s. The L92 is very similar to the LS3 but with truck intake and oil pan, truck/SUV ECM programming, and its use of VVT. The L92 also utilizes many high-tech features previously discussed for the LS3, including:

Applications and Power: 2007-2008 GMC Yukon Denali / GMC Yukon XL Denali - 380hp / 417lb-ft LY6Generation: IV

Notable Features: The LY6 is the iron block / aluminum head Gen IV 6.0L workhorse truck engine, replacement for the Gen III LQ4. The LY6 features VVT. Like the L92, the LY6 features many advanced Gen IV features including:

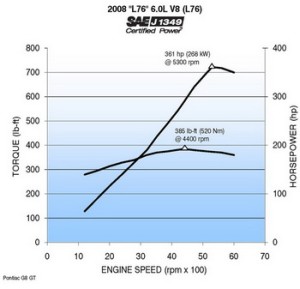

L76Generation: IV

Notable Features: The L76 is the all-aluminum Gen IV 6.0L, lightweight, H.O. version of the LY6 and is the replacement for the Gen III LQ9 for use in trucks and SUV’s. The L76 features AFM, VVT, and ETC. Like the L92 and LY6, the L76 features many advanced Gen IV features including:

Unlike the L92 and LY6, the L76 also uses AFM, described above in the section on Gen IV technologies. L9HGeneration: IV

Notable Features: The L9H is the latest, most powerful all-aluminum Gen IV Vortec (truck) V8 from GM for select 2009 trucks and SUV’s. It replaces the L92 as the top-of-the line GM truck engine. Unlike the L92 it is equipped for E85 flex-fuel use. It has VVT. Like the L92, LY6, and L76 the L9H features many advanced Gen IV features including:

It has the following L9H specific features:

Like other Gen IV Vortec V8’s, the L9H is equipped with high-flow cylinder heads based on those developed for the high-performance LS2 and LS6 car V8s. These heads have offset rockers, like those in the LS7. They also have larger valves than other Vortec V8 heads, and increase airflow in and out of the engine for higher horsepower. The L9H cylinder heads feature special valve seat inserts to accommodate the engine’s use of for E85 fuel. A special high-lift cam, with 12.7 mm. maximum lift, was further refined to take full advantage of the VVT, improved flow characteristics and to optimize idle quality. In conjunction with unique pistons, the high-flow heads give the L9H a 10.5:1 compression ratio. On the L9H a new low modulus A/C compressor belt was employed. This design eliminates the need for a separate belt tensioner, further simplifying the design and reducing mass. Applications: 2009 Chevrolet Tahoe LTZ / Chevrolet Silverado LTZ Gen III/IV Motors by Displacement

GM V8 Timeline

Weights & DimensionsLS1 bare intake – 8lbs Motor Measurements

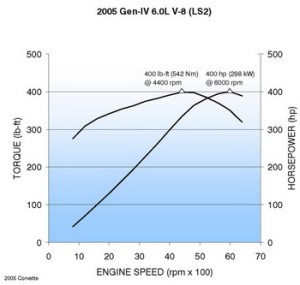

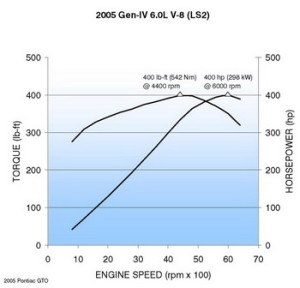

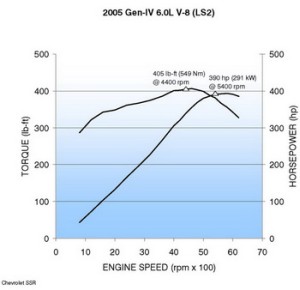

Car vs. TruckAs we’ve discussed, the Gen III/IV architecture is broadly common across all platforms. Obviously, motors of different displacement use different blocks and bottom ends (cranks, rods, pistons, etc.). Of course, even very similar motors of the same displacement have differences between them when used in different platforms. The differences can be as large as different heads, valves, cams, and ECM programming or as minor as the style of air intake and vanity covers. With that said, motors of the same displacement are quite similar whether they are “car” or “truck” motors, but there are some common differences that are worth being aware of: Block material The iron block motors also have exceptionally strong blocks because the block design was engineered to be strong enough in aluminum, so the extra strength of cast iron over aluminum makes the iron block very strong. This makes the iron-block motors great candidates for building supercharged or nitrous-fed animals. Weight Height – intake and oil pan Price AFM / VVT Miscellaneous Power & Truck Intake One often-claimed enduring myth related to the difference between truck and car motors relates back to the taller truck intake. It is often claimed that the taller truck intake “makes better low-end torque” than the equivalent car intake. This is not correct. First, the reason the truck intake is so much taller than the car intake is not because it was designed specifically to make “better” low-end torque than a car – it is taller because it needs to be so the throttle body can clear the much larger radiator / fan used in the trucks and SUV’s. That is not to say that the truck engines with tall truck intakes don’t make excellent power – down low and up high – they do! But I think it is incorrect to suggest that in identical motors, one equipped with a truck intake and one with a car intake, the truck engine would make “better” low-end torque. To prove my assertion, I offer the following evidence: The LS2 and L76 were used in both cars and trucks in the same year, as shown below:

Note the intakes, accessory packages, and oil pans are different between the cars and trucks. The same is true for the L76 below:

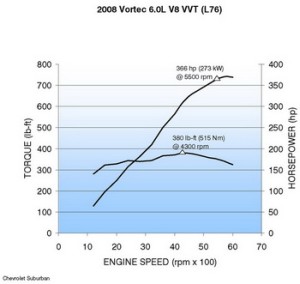

So, we have the closest examples we're likely to find to identical motors with different intakes - car and truck. If the myth were true, we should expect to find noticeably different HP/ torque curves on the respective dyno graphs. However, when we examine the graphs for these exact engines, below, we find no such differences. There are some minor differences between the exact curves, attributable to any number of small differences like ECM and exhaust, but certainly nothing that would allow the claim "truck intakes make better low-end torque than car intakes." Sorry - it just aint so!

Careful examination of the stock performance curves reveals that there are essentially very little difference in the low end torque produced, certainly not enough to justify ever choosing a truck engine over a car motor for this mythical benefit. Minor differences are much more likely to be attributable to the host of small differences – ECM programming and such, than to the height of the intake. Bottom line, both motors are so well engineered, so well optimized, and so well controlled by the ECM that they both make excellent power across the entire RPM range. Gone are the days of having to choose between low-end torque or high hp performance at the top end. In summary, a desire for low-end torque probably shouldn’t be used as a basis for choosing a truck motor over a car motor. Heck – my Turn Key Engine Supply built “car” LS2 never makes less than 400 ft-lbs of torque throughout its entire range!! Accessories

Choosing a Gen III/IVSo, now that you know everything about Gen III/IV motors, the meat of the question is: “how do you choose one?”, or perhaps, “How do I evaluate whether this motor I found a good deal on will be ok for my needs?” In the case of the former, the ultimate answer would be call a company like Turn Key to custom build you any thing your heart desires. Very shortly I will be offering an exclusive in-depth look at this dream option by publishing an unprecedented, detailed look at the 525hp LS2 recently built for me by Turn Key Engine Supply – from the engine build to the dyno sheet to the details of every accessory and part included in the package. In the meantime, I offer you this: Personally, I would always choose an all-aluminum “car” motor over any other option, if I could, for the following reasons:

That said, truck motors do have some advantages of their own:

FAQ and FactoidsA bunch of interesting (maybe) stuff I couldn’t be bothered to fit anywhere else. ETC summaryETC, also known as "Drive by Wire" or “Throttle by Wire” requires a special pedal, harness and control module. There is no throttle cable, or direct connection between the throttle pedal and the throttle plate in the throttle body. Instead, the pedal sends electronic signals to the ECM. The ECM controls a Throttle Actuator Control (TAC) module which then operates the electric motor that opens and closes the throttle. ETC engines are easy to spot because of the electric motor assembly clearly visible on the side of the throttle body. Some applications Electronic Throttle Control (ETC) was used on include:

ETC was originally conceived and designed to enable better traction control to make the 400hp Corvette drivable by ordinary people. “Advanced” ETC (on all ETC motors from the 2006 LS2 and up) deletes the need for a separate TAC and uses only the E38 and later ECM for operation and control. Depths of Different Oil PansLS7 – dry sump - 4.5” Bat-wing Vette – 4.75” (C5 corvette (with LS1) Corvette – 5” (non bat-wing) Camaro/Firebird – 5.5” GTO – front sump – 6” Cadillac CTS-V – 6.75” Hummer H3 5.3L – 7.5” Truck 8.25” An F-body (Camaro/Firebird) LS1 oil pan makes the bottom of the oil pan level with the bottom of a TH400 transmission pan. When swapping an oil pan you need the pan, the dipstick and tube, the pickup tube, and the gasket. MiscellaneousAll the fasteners used on Gen III/IV motors are metric! Assuming you are buying from a trustworthy source, you can run the VIN to see what motor you're dealing with. (Read 8th position of the VIN: "N" = LQ9 "U" = LQ4) A scan tool can pull it from the PCM if you don't have access to the VIN plate or the registration/title. Stock Gen III/IV motors come stock with specific "self protection" programming included in the ECM code. One example is a program called "torque management". The idea is, under certain circumstances, the ECM automatically reduces engine power produced to protect the drivetrain. It makes sense for an ordinary vehicle (especially for GM while said vehicle is under warranty) but isn't much use to enthusiasts. It's said the aftermarket computer re=programming alone can reliably net 10% gains in gross power - 30-40hp! In vehicles that use the same RPO engine, but have different HP/TQ ratings, it is most often air intake assembly, exhaust manifolds and exhaust, and different programming in the ECM that accounts for the differences. Rumour has it that sometimes GM also intentionally underrates certain engines in certain model vehicles to keep happy the owners of the higher-end vehicles that use the same engine. For example, a Cadillac Escalade and GMC Denali may use the same motor, but the Caddy will always be rated higher as it commands a higher price. This may just be wishful thinking urban legend though. GM publishes a 5.7L LS1 swap guide (PN 88959384) that is a good source for swapping Gen III engines. Cam swapping in Gen III/IV motors is easier than in previous motors. With earlier small-block engines, you have to yank the intake manifold and then remove the lifters before the cam will come out. The Gen III/IV engines employ a plastic roller-lifter retainer that captures the lifters so you don't have to remove the intake. Just pull the rockers off to unload the lifters, spin the engine around two revolutions, and you're ready to go. The “cathedral style” intake ports on early Gen III motors came about as a result of the lack of room between the head bolts and the in-line pushrods. LQ4/LQ9 truck engine aluminum heads have the same ports as the LS6 but slightly larger combustion chambers for the truck compression ratio (LQ4/LQ9 = 72cc, LS6 = 64cc). The 4.8 & 5.3 litre cast iron truck blocks (Gen III and IV) can easily be bored to 5.7L size. The 4.8 requires a longer-stroke crank to achieve this displacement, but the 5.3 can become a 5.7L with the stock crank. The cast-iron 6.0L engines already have a 4.000” bore which is pretty much the max so they aren’t good candidates for an overbore to gain displacement. On most Gen III/IV aluminum blocks the the piston bores are actually thin centrifugally cast-in-place cast iron liner with a serrated outside diameter that bites into the aluminum block. These thin cast iron liners are the reason there is a strict (and small) limit on how much an aluminum block can be honed / bored. Gm recommends only 0.004” (little more than a surface honing) on 97-98 LS1 blocks, and only 0.010” on 99+ blocks. This isn’t a huge deal though as fortunately the aluminum Gen III/IV motors are produced with stock displacements from 4.8 to 7.0 litres and have a designed service life of 400,000 kms. Rotation (of crankshaft), viewed from front: clockwise. Head bolts are non-reusable “stretch to torque” style. LS1 exhaust ports are oval,LS6 ports are “D” shaped. The stock nodular cast iron crank has consistently shown it can handle 500+ hp, as have the stock cast eutectic aluminum pistons. Much over 500 and both should probably be replaced with stronger forged pieces. The cast-iron block can easily handle 800hp. Gen III/IB cranking fuel pressure: 53 – 63 psi. Truck Strokes: The LS6 intake (dropped floor, more volume, better flow, no EGR compared to LS1) became the standard LS1 intake as well in 2001. The OD of the Gen III cam bores was changed for model year '04, so the later engines require a different set of cam bearings, even though the cam and everything else stayed the same. All the head bolts have blind holes, so rebuilders need to make sure there's no debris or oil in them before torquing the head bolts down, because the hydraulic pressure will split the block wide open if there's anything left in the hole. The 4.8L piston is a flat top, but the 5.3L is dished because they both use the same head, so the 5.3L with the longer stroke would have had too much compression with a flat top piston. The LS1 pistons are made of a good, standard aluminum alloy that was more than adequate for a regular motor, but the pistons for the LS6 pistons were made of a premium alloy that had more copper and nickel in it so they were stronger and they didn't expand quite as much when they were hot. The additional strength was important in a performance motor, but the lower expansion rate was more important because it allowed GM to run tighter bore clearances which reduced noise and lowered oil consumption. The 6.0L pistons were all flat tops, but the ones used for the 6.0L LQ9 had a moly coating on the skirts and a thermal barrier on the top. All of the Gen III pistons have had a moly coating on the skirts since 2003. Cams The cam used in the '02-'04 LS6 had a smaller base circle so the valves were 0.6 mm longer to compensate for the difference. That means this cam can't be interchanged with any other cam unless all the matching components are used, too. Cylinder Heads '97-'98 LS1 - The original LS1 heads were 10215339 or 12558806 castings that had 66.7cc chambers and nine bolts around the perimeter to hold the rocker covers on. '99-'04 LS1 - The LS1 switched to centre-bolt rocker covers in '99, so these engines came with a new head. These heads have 66.7cc chambers, too. '01-'04 LS6 - The LS6 performance engines had the 12564243 castings that flowed more air due to better intake ports and the "D" shaped exhaust ports. The chamber was a little smaller (61.15cc) so the engine had a slightly higher compression ratio, too. The cast iron head on the '99-'01 truck 6.0L engines was a 12561873 casting. All of the '01- '04 6.0L engines had an aluminum head with a 12562317 or 12572035 casting number. These heads were used on all the 6.0L motors including the standard LQ4 and the LQ9 performance motor. They're easy to recognize because they have the same "D" shaped exhaust ports that were found on the LS6 heads. Valves The LS6 used lightweight valves with hollow stems starting in '02. The hollow intakes saved some weight, but the hollow exhausts were filled with sodium so they ran cooler. Both of these valves are 0.6 mm longer than the others because the cam for the '02 LS6 had a smaller base circle. Gen III/IV pushrods are longer than the ones for the Gen I/II motors and they have thicker walls. The aluminum blocks are very sensitive to main bearing clearances and cam bearing clearance because they will increase when the engine gets hot. GM changed the length of some of the head bolts in 2004. The '99-'03 engines had 16 long ones, (6.50” overall length) and four short ones, (4.40” overall length) along with 10 small 8.0 mm bolts. In '04, GM started using all short bolts (4.40”) to avoid the stripped threads that were caused when people put the short ones in the deep holes and tried to torque them down. All of the 5.3L engines got the LS1-style heads with the "D"-shaped exhaust ports in 2004. The dished pistons were replaced by flat-tops, too. Turn Key Engine SupplyConclusionThe third and fourth generation GM small block V8 engines are a technological tour-de-force and breathtaking example of simple, elegant engineering. They have to rank as one of the greatest “told-you-so” stories of all time as they resoundingly proved the naysayers wrong and showed that pushrod engines are anything but washed-up old-school. In my opinion they also have to rank as some of the very finest motors ever conceived, engineered and built. Smaller, lighter, making more horsepower and torque per cubic inch, creating fewer emissions, and more fuel efficient than the legendary Chevy small-blocks they replaced they are a resounding success. The Gen III/IV engines profit from excellent simplicity and elegant engineering built into the design. They produce more power more efficiently than multi-cam engines that cost significantly more to build. They represent a significant and distinguished accomplishment in engineering. References:Books:How to Build High-Performance Chevy LS1/LS6 V-8s by Will Handzel Chevy LS1/LS6 Performance: High Performance Modifications for Street and Racing by Chris Endres How to Rebuild GM LS-Series Engines by Chris Werner Websites:Peterson's 4Wheel & Offroad 6.0L Engine Swap Article Part 1 Peterson's 4Wheel & Offroad 6.0L Engine Swap Article Part 2 Gen III GM smallblock by Doug Anderson @ engine-builder.com The Millennium Motor: Inside The LS1 by Hib Halverson GM's LS2 V8 - article at Autospeed.com Technical Article: The Millennium Motor: Inside C5’s, LS1 Engine by Hib Halverson Project Light Speed Part 3 - 49hp LS1 Engine Cam Swap - Tech Article @ CarCraft.com by Jeff Smith Ruthless Pursuit of Power: GM Brings us to the next Gen III: LS6 by Hib Halverson Ruthless Pursuit of Power: The Sequel 2002 LS6 by Hib Halverson Corvette LS3 Engine - Worthy Successor - Article in Vette Magazine by Christopher R. Phillip Other:GM Performance Parts Catalogue 2008 GM Performance Parts Cattalo 2009 GM's LS1 Engine Kit Installation Guide |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sources: Turn Key Engine Supply 2620 Temple Heights Dr.

|

|

_resize.jpg)

_resize.jpg)

for HUMMER H2 - David Kimble Illustration_resize.jpg)

X09PT_8C081_resize.jpg)